1932

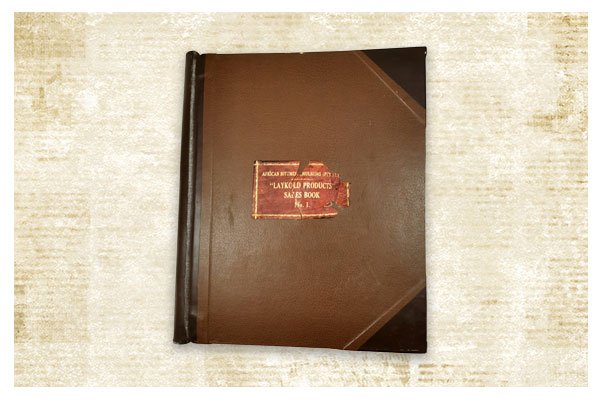

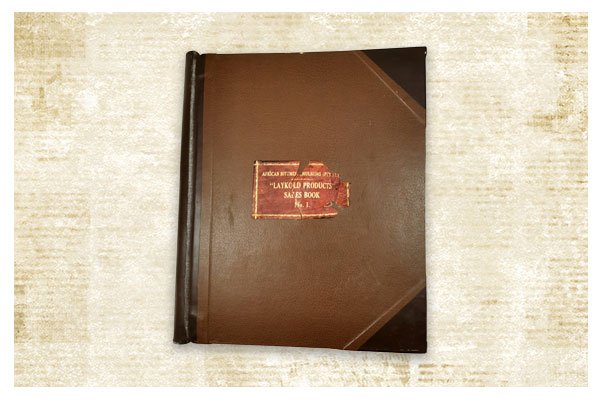

It took courage, back in 1932, to start a new business while an impoverished world was in the middle of the most severe economic depression ever.

Yet the Durban founders of African Bitumen Emulsions did just that. Today, 90 years later, their brave new enterprise, now called a.b.e. Construction Chemicals, is very much alive and a dynamic market leader in sub-Saharan Africa.

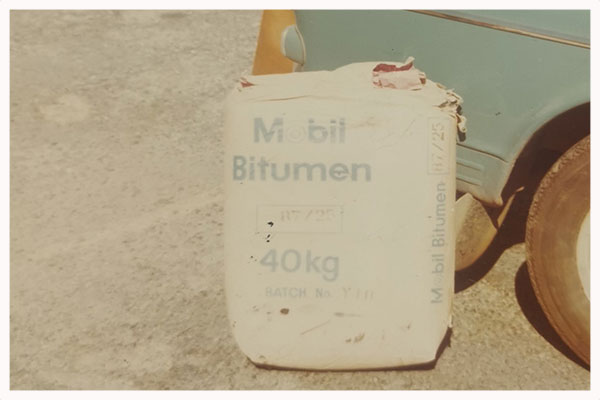

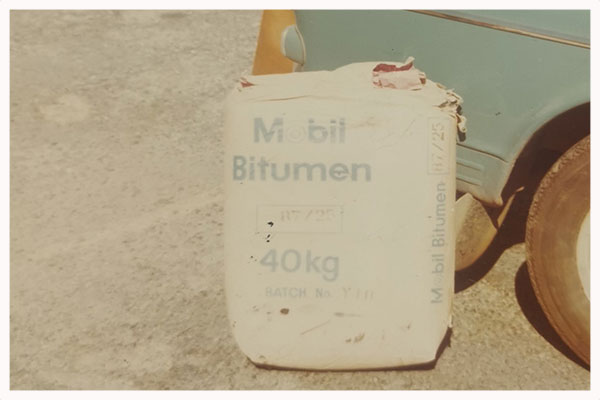

a.b.e. operations in Durban, started out as a humble supplier of bitumen to what were then Natal municipalities.

Further operations were established in Johannesburg from 1940, in Cape Town from 1950, and in Port Elizabeth from 1953.

1939

1941

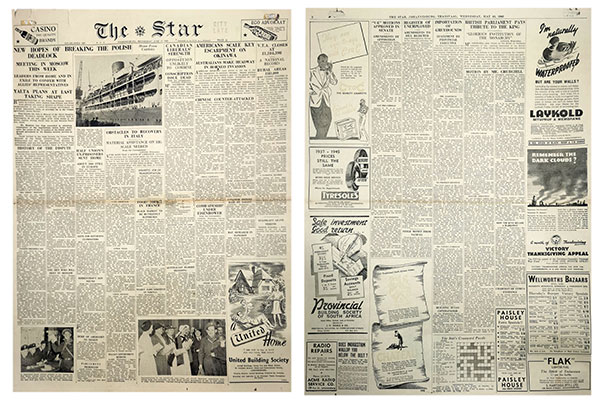

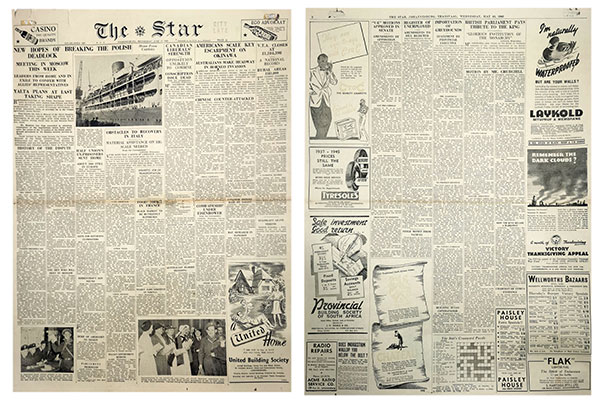

Distribution through retail outlets commenced and advertising its product became relevant.

Reference: The Star – Johannesburg, Transvaal, Monday, August 1941. LAYKOLD – BITUPRUF & MEMBRANE.

A bitumen-liked product produced in Durban so many decades ago has become a household name in the hardware industry.

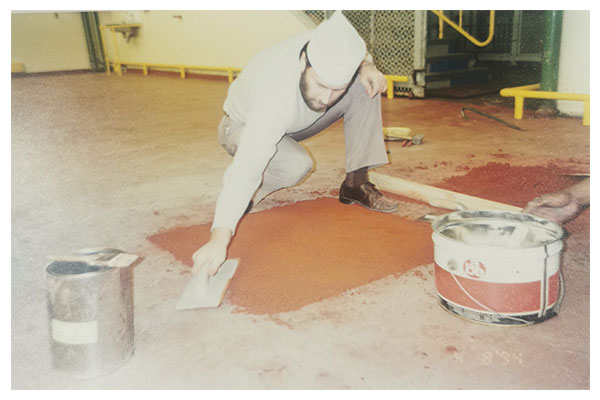

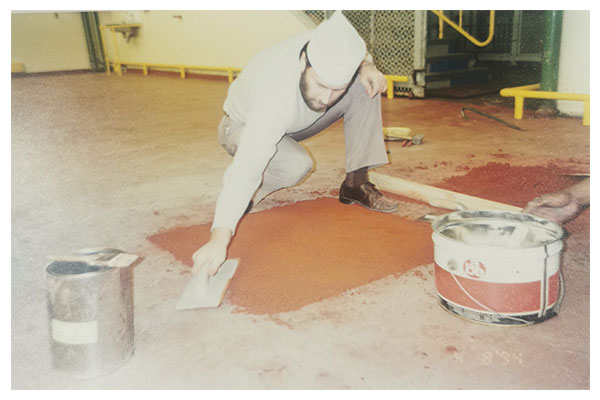

a.b.e. started a flooring and adhesives division when the need for floor coating solutions became much needed.

1946

1955

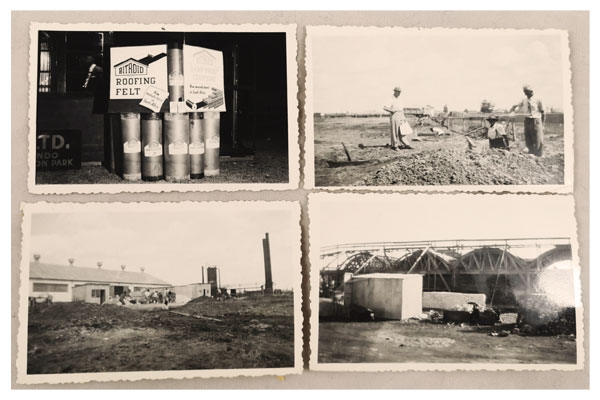

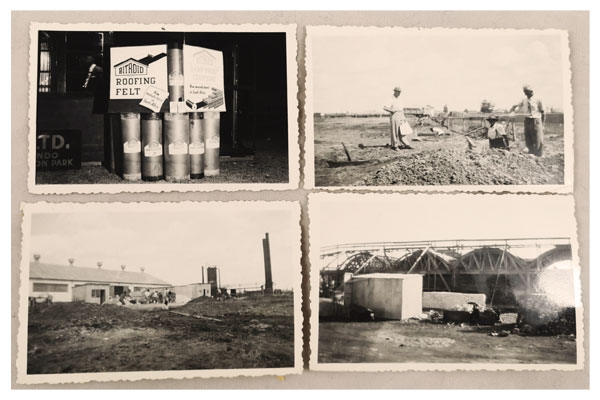

The destruction of large urban areas of Britain by bombing during the Second World War, created a need for the development of cheap affordable housing. Consequently, the 1950s and 1960s saw a proliferation of flat-roofed buildings and an expansion in the use of primitive roofing felts. In the 1950s bithoid was used in South Africa as roofing felt and damp proof course (DPC) in the building industry.

SHELL acquired 50% of African Bitumen Emulsions from the founders during this time.

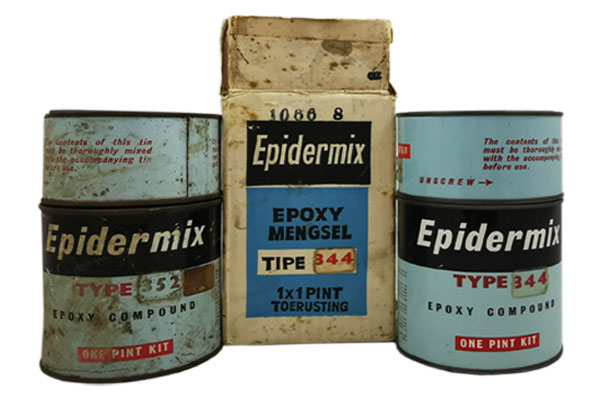

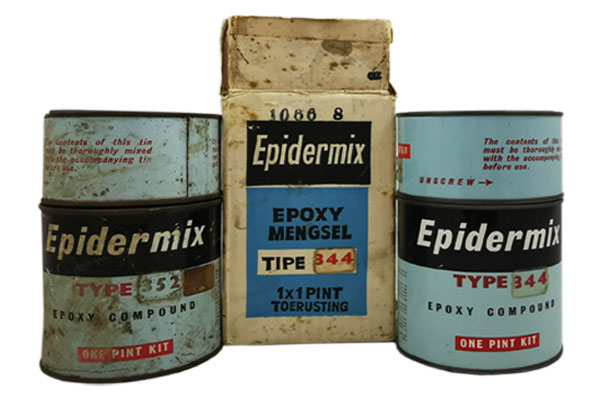

The Flooring & Adhesives division started the epidermix product brand, which also became a well-known product range for a.b.e. today.

1965

1975

Murray & Roberts acquired the other 50% and together with SHELL, a.b.e. become a new holding company called ABECOL.

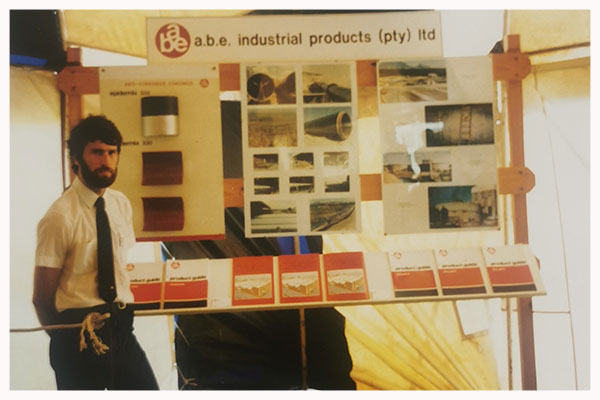

Consequently, the Industrial & Roads division was established, with operations expanding to East London and Bloemfontein.

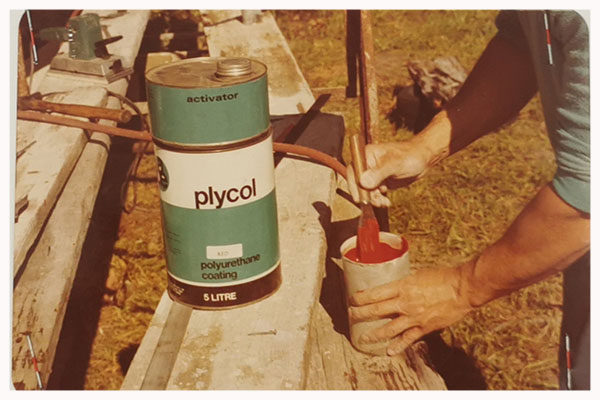

PUs was first discovered in 1937 by the textile industry and from further research demonstrated the reaction of an aliphatic isocyanate with a glycol, producing new materials with interesting properties like the desirable elastic properties. Only after the war in 1952 polyisocyanate become available. PU coatings opened the door for automotive applications and different types of PU coatings are used in construction for environmental deterioration protection.

1979

1980

Major abecote flooring projects during this time included:

- Robertson’s Spices processing and packaging plant, Prospecton.

- Rainbow Chickens packaging plant, Hammersdale.

- Southern Star Organisation workshop, Port Elizabeth.

- Berkshire International manufacturing plant, Woodbrooke.

- Volkswagen South Africa paint workshop, Uitenhage.

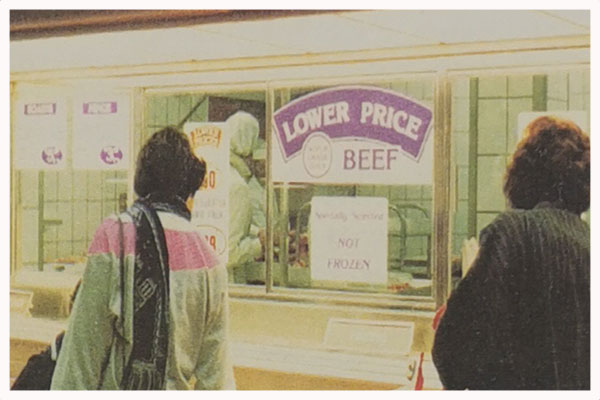

A new look for Woolworths Wynberg, Cape Town floors – formulated to Woolworths’ preferred colour, with a.b.e.’s 8mm abescreed mortar finish.

1985

1989

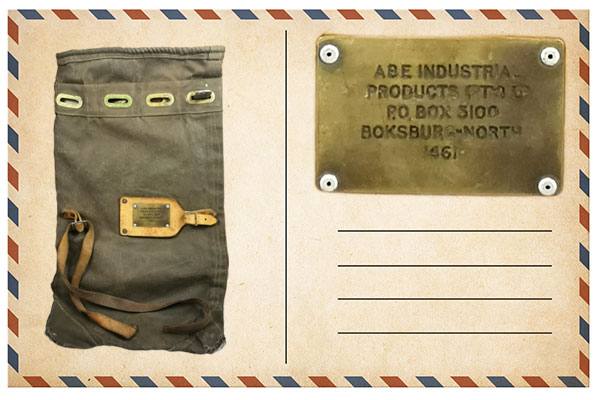

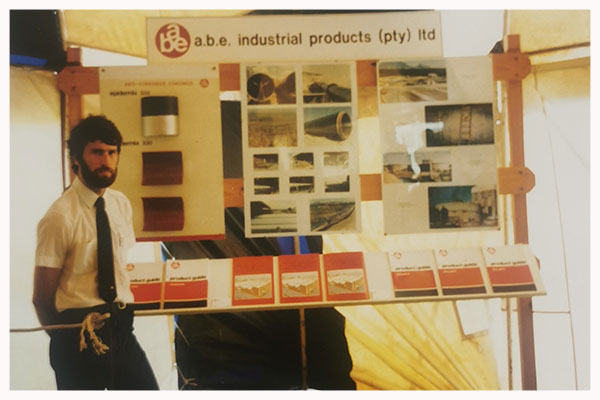

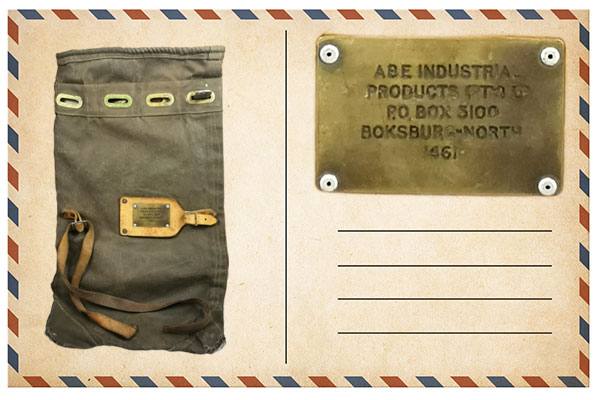

The company becomes a 100% subsidiary of Murray & Roberts, called a.b.e. Industrial Products.

A further acquisition realised of Embacon SA.

During the 90s a.b.e. grew in both size and diversity to become a major supplier of specialised construction products to the building, civil engineering and building maintenance industries. These products included its locally-produced ranges and the distribution of Index, Fosroc, Silcart and Dow Corning (now Dowsil).

1993

Chemserve acquires 50% from Murray & Roberts in 1996 and in the next year M & R sold the other 50% to Steelwood Africa.

a.b.e. expanded its supply of specialised products through a newly created Retail Division.

1997

1999

a.b.e. became a 100% subsidiary of the KYD Steelwood Africa Group, with another decennial future growth waiting and now called a.b.e. Construction Chemicals.

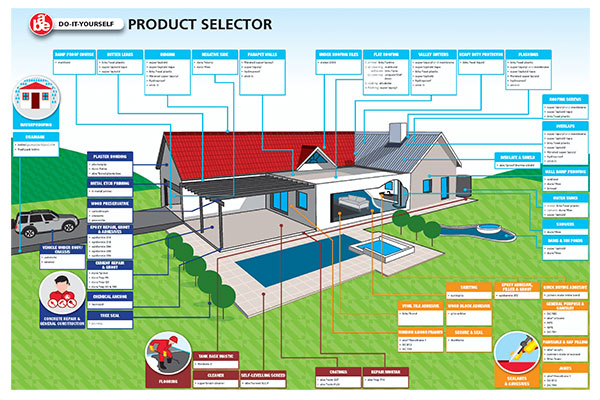

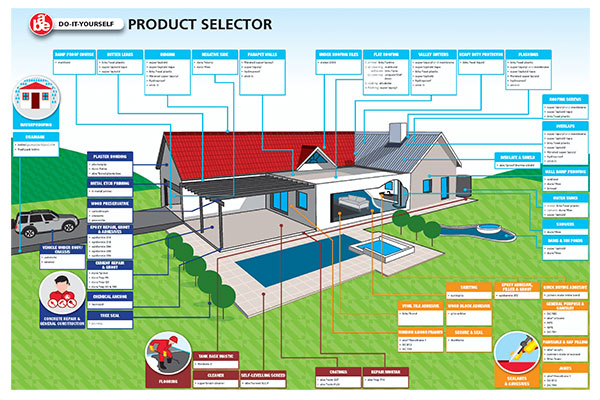

Showcasing its different brands and product solutions to both the construction and retail markets, supplied through a network of branches and distributors across South Africa, sub-Saharan Africa, and the Indian Ocean Islands.

During this time a 26% BBBEE acquisition by Auburn was acquired in a.b.e. Construction Chemicals by 2009 listed on the JSE AltX Exchange.

2007

2010

a.b.e. delisted from the AltX and was acquired by CHRYSO, part of Materis.

A two-year plan to upgrade production facilities commenced, including departmental and branch restructuring to increase efficiencies and improve customer service.

Key Account sales focus and new product listings added to the sales growth, with a strong Flooring team and product basket being implemented.

New powder laboratory established implementing significant QC programmes.

R&D initiatives had resulted in optimised products, improved quality, and performance.

Powder products were screened to reduce the carbon footprint in the construction industry and provide “dustless” powders.

Launched a new eco-friendly, high performance, waterproofing range which was met nationally with overwhelming acceptance and enthusiasm from prospective architects and contractors. These products enhance performance and allow for quicker turnaround times.

2011

2012

2012/2013

Continued implementation of product range development, organisation of market approach like combined branches, safety initiatives and sustainability development plans.

New company corporate identity and packaging identity were implemented.

CHRYSO Group was acquired by LBO France.

VIP Polyurea product distribution in South Africa completed the company’s product offering for waterproofing, flooring, and coatings.

Self-levelling screed underlay solutions were launched to gain flooring market share.

2014

2015

2015/16

Despite strong competition, a.b.e. sales growth in 2014 continued, driven by the launch of new products like Dowsil façade cladding system, inroads into Africa combined with Chryso market knowledge, DDMRP program implantation, and significant market share gains with further combined company approach.

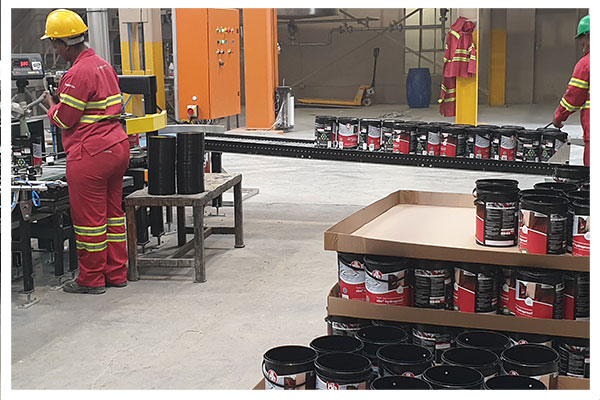

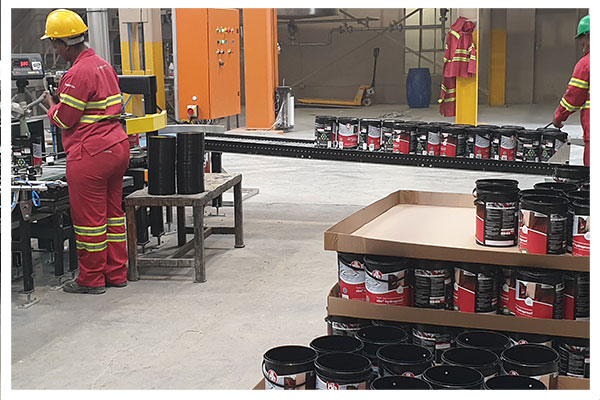

a.b.e. continued to invest in expansion and improved manufacturing plants. Further expenditure projects for both the a.b.e. Boksburg liquid and powder plant have already started and the a.b.e. Isipingo plant was also investing in new packaging lines.

The company’s commitment to safety also remained of paramount concern, and the Group’s Die Meerkat Way OH&S program endorsed the commitment to the safety of all.

The company held ISO9001 accreditation for its Boksburg, Isipingo, and Mount Edgecombe factories and offices, and its other operations would also be ISO9001-compliant during 2015. The company progressed to have all its branches OSHAS18001-accredited in the same year.

2017

2017 /18/19

International private equity firm Cinven acquired CHRYSO from LBO France, a.b.e. still a CHRYSO group company. This project will allow the CHRYSO Group to fully support its ambitious strategy to become a global leader.

Despite continued volatile market conditions, a.b.e. maintained its growth strategy by launching new products; strengthening its marketing by creating a SAF Group Communications department; and by a Best Practice production injection for maximisation of workflow, increased automation, slashed production costs.

2020/21

International virus COVID-19 hit South Africa in March 2020 with continued lockdowns for two-years and interrupted trading for businesses.

a.b.e. had a strong standing and with previous years’ growth strategies stood the test of time, with continued new products being offered to the retail hardware and construction industry and implemented production efficiencies.

The 2006 hydroproof production line at the Boksburg liquid plant was extended to manufacture four more similar product lines for the retail/DIY market segment.

The abescreed self-levelling underlay also extended with more product variants to satisfy the current flooring market demand.

By the end of 2021 CHRYSO Group was acquired by Saint-Gobain.

2020

a.b.e. is part of Saint-Gobain Africa’s company brands portfolio.

2022

1932

It took courage, back in 1932, to start a new business while an impoverished world was in the middle of the most severe economic depression ever.

Yet the Durban founders of African Bitumen Emulsions did just that. Today, 90 years later, their brave new enterprise, now called a.b.e. Construction Chemicals, is very much alive and a dynamic market leader in sub-Saharan Africa.

1939

a.b.e. operations in Durban, started out as a humble supplier of bitumen to what were then Natal municipalities.

Further operations were established in Johannesburg from 1940, in Cape Town from 1950, and in Port Elizabeth from 1953.

1941

Distribution through retail outlets commenced and advertising its product became relevant.

Reference: The Star – Johannesburg, Transvaal, Monday, August 1941. LAYKOLD – BITUPRUF & MEMBRANE.

A bitumen-liked product produced in Durban so many decades ago has become a household name in the hardware industry.

1946

a.b.e. started a flooring and adhesives division when the need for floor coating solutions became much needed.

1955

The destruction of large urban areas of Britain by bombing during the Second World War, created a need for the development of cheap affordable housing. Consequently, the 1950s and 1960s saw a proliferation of flat-roofed buildings and an expansion in the use of primitive roofing felts. In the 1950s bithoid was used in South Africa as roofing felt and damp proof course (DPC) in the building industry.

1965

SHELL acquired 50% of African Bitumen Emulsions from the founders during this time.

The Flooring & Adhesives division started the epidermix product brand, which also became a well-known product range for a.b.e. today.

1975

Murray & Roberts acquired the other 50% and together with SHELL, a.b.e. become a new holding company called ABECOL.

Consequently, the Industrial & Roads division was established, with operations expanding to East London and Bloemfontein.

1979

PUs was first discovered in 1937 by the textile industry and from further research demonstrated the reaction of an aliphatic isocyanate with a glycol, producing new materials with interesting properties like the desirable elastic properties. Only after the war in 1952 polyisocyanate become available. PU coatings opened the door for automotive applications and different types of PU coatings are used in construction for environmental deterioration protection.

1980

- Robertson’s Spices processing and packaging plant, Prospecton.

- Rainbow Chickens packaging plant, Hammersdale.

- Southern Star Organisation workshop, Port Elizabeth.

- Berkshire International manufacturing plant, Woodbrooke.

- Volkswagen South Africa paint workshop, Uitenhage.

1985

A new look for Woolworths Wynberg, Cape Town floors – formulated to Woolworths’ preferred colour, with a.b.e.’s 8mm abescreed mortar finish.

1989

The company becomes a 100% subsidiary of Murray & Roberts, called a.b.e. Industrial Products.

A further acquisition realised of Embacon SA.

1993

During the 90s a.b.e. grew in both size and diversity to become a major supplier of specialised construction products to the building, civil engineering and building maintenance industries. These products included its locally-produced ranges and the distribution of Index, Fosroc, Silcart and Dow Corning (now Dowsil).

1997

Chemserve acquires 50% from Murray & Roberts in 1996 and in the next year M & R sold the other 50% to Steelwood Africa.

a.b.e. expanded its supply of specialised products through a newly created Retail Division.

1999

a.b.e. became a 100% subsidiary of the KYD Steelwood Africa Group, with another decennial future growth waiting and now called a.b.e. Construction Chemicals.

Showcasing its different brands and product solutions to both the construction and retail markets, supplied through a network of branches and distributors across South Africa, sub-Saharan Africa, and the Indian Ocean Islands.

2007

During this time a 26% BBBEE acquisition by Auburn was acquired in a.b.e. Construction Chemicals by 2009 listed on the JSE AltX Exchange.

2010

a.b.e. delisted from the AltX and was acquired by CHRYSO, part of Materis.

2011

A two-year plan to upgrade production facilities commenced, including departmental and branch restructuring to increase efficiencies and improve customer service.

Key Account sales focus and new product listings added to the sales growth, with a strong Flooring team and product basket being implemented.

New powder laboratory established implementing significant QC programmes.

R&D initiatives had resulted in optimised products, improved quality, and performance.

Powder products were screened to reduce the carbon footprint in the construction industry and provide “dustless” powders.

Launched a new eco-friendly, high performance, waterproofing range which was met nationally with overwhelming acceptance and enthusiasm from prospective architects and contractors. These products enhance performance and allow for quicker turnaround times.

2012

2012/2013

Continued implementation of product range development, organisation of market approach like combined branches, safety initiatives and sustainability development plans.

New company corporate identity and packaging identity were implemented.

2014

CHRYSO Group was acquired by LBO France.

VIP Polyurea product distribution in South Africa completed the company’s product offering for waterproofing, flooring, and coatings.

Self-levelling screed underlay solutions were launched to gain flooring market share.

2015

2015/16

Despite strong competition, a.b.e. sales growth in 2014 continued, driven by the launch of new products like Dowsil façade cladding system, inroads into Africa combined with Chryso market knowledge, DDMRP program implantation, and significant market share gains with further combined company approach.

a.b.e. continued to invest in expansion and improved manufacturing plants. Further expenditure projects for both the a.b.e. Boksburg liquid and powder plant have already started and the a.b.e. Isipingo plant was also investing in new packaging lines.

The company’s commitment to safety also remained of paramount concern, and the Group’s Die Meerkat Way OH&S program endorsed the commitment to the safety of all.

The company held ISO9001 accreditation for its Boksburg, Isipingo, and Mount Edgecombe factories and offices, and its other operations would also be ISO9001-compliant during 2015. The company progressed to have all its branches OSHAS18001-accredited in the same year.

2017

2017 /18/19

International private equity firm Cinven acquired CHRYSO from LBO France, a.b.e. still a CHRYSO group company. This project will allow the CHRYSO Group to fully support its ambitious strategy to become a global leader.

Despite continued volatile market conditions, a.b.e. maintained its growth strategy by launching new products; strengthening its marketing by creating a SAF Group Communications department; and by a Best Practice production injection for maximisation of workflow, increased automation, slashed production costs.

2020

2020/21

International virus COVID-19 hit South Africa in March 2020 with continued lockdowns for two-years and interrupted trading for businesses.

a.b.e. had a strong standing and with previous years’ growth strategies stood the test of time, with continued new products being offered to the retail hardware and construction industry and implemented production efficiencies.

The 2006 hydroproof production line at the Boksburg liquid plant was extended to manufacture four more similar product lines for the retail/DIY market segment.

The abescreed self-levelling underlay also extended with more product variants to satisfy the current flooring market demand.

By the end of 2021 CHRYSO Group was acquired by Saint-Gobain.

2022

a.b.e. is part of Saint-Gobain Africa’s company brands portfolio.