Two part silicone rubber

Applications

Two-part silicone sealant for structural glazing.

Features & Benefits

- Meets European standard for structural glazing as developed by EOTA working groups.

- Excellent adhesion to a wide range of substrates including coated, enamelled and reflective glasses, anodised and polyester paint coated aluminium and stainless steel.

- High level of mechanical properties.

- Odorless and non-corrosive cure.

- Excellent stability through wide temperature range: -50ºC to 150ºC.

- Resistant to ozone.

- Stable viscosity for A & B components, no heating required.

- Suitable for use in impact-resistant window systems in new construction and retrofit in existing buildings.

- Structural capability.

- The cured product exhibits excellent weathering characteristics, and a high resistance to ultra-violet radiation, heat and humidity.

- Lot matching of base and curing agent not necessary.

- Different gray shades available (please refer to our colour card).

Typical Properties

*See datasheet

Description

DowSilTM 993 Structural Glazing Sealant is a two-component, neutral curing silicone formulation specifically developed for the structural bonding of glass, metal and other building components.

Neutral alkoxy; cures at room temperature giving off a small amount of alcohol.

Technical Specifications & Standards

DowSilTM 993 Structural Glazing Sealant offers unprimed adhesion to most coated and uncoated glasses as well as most metal spacers. The sealant is compatible with DowSilTM Neutral Curing Construction Sealants such as DowSilTM 791 Silicone Weatherproofing Sealant, and DowSilTM Neutral Curing Insulating Glass Sealants such as DowSilTM 3362 HD Insulating Glass Sealant, as well as most commonly used glazing components. It is important when selecting components for a project that adhesion and compatibility tests are carried out, and found to be successful, before the project starts.

Mixing and dispensing

To obtain the ultimate physical properties from DowSilTM 993 Structural Glazing Sealant it is recommended that the base and curing agent are thoroughly mixed using an airless mixing system found on most existing commercially available two-part silicone dispensing machines. Only special, two part hand mixed cartridge systems endorsed by Dow Corning® should be used to avoid incorporation of air into the material.

DowSilTM 993 Structural Glazing Sealant should be mixed in a ratio of 10:1 base to curing agent by weight, or equivalent 7.8:1 by volume for optimal properties. At this mix ratio, the sealant typically exhibits a working time of 10-30 minutes and allows units to be handled within two hours. Small variations in mixing ratio can be tolerated, but these should not exceed 11:1 to 9:1 by weight or 8.9:1 to 7.3:1 by volume to ensure minimum properties are obtained.

Lot matching of DowSilTM 993 Base and DowSilTM 993 Curing Agent is not required. Before use it is recommended that the curing agent be stirred to ensure homogeneity of all components. DowSilTM 993 Curing Agent will react with atmospheric moisture and therefore should not be exposed to air for prolonged periods of time.

Different catalysts are available for DowSilTM 993 Structural Glazing Sealant:

DowSilTM 993 Structural Glazing Catalyst is a medium viscosity paste, fast cure, which is suitable for meter mix equipment using a pressure pot or follower plate system for the catalyst.

DowSilTM 993 HV/GER Structural Glazing Catalyst is a viscous paste, fast cure, which is suitable for meter mix equipment that uses a follower plate system for the catalyst.

Preparatory work

Clean all joints and glazing pockets, removing all foreign matter and contaminants such as grease, oil, dust, water, frost, surface dirt, old sealants, or glazing compounds and protective coatings.

Metal, glass and plastic surfaces should be cleaned by mechanical or solvent procedures. Where used, solvent should be wiped on and off with clean, oil- and lint-free cloths.

Priming

Priming is not usually required when using DowSilTM 993 Structural Glazing Sealant. However, it is essential that adhesion be tested prior to use. Specific primer recommendations will be made by Dow Corning Technical Services Department on a project basis. Please contact Dow Corning for further advice.

Masking and tooling

Areas adjacent to joints may be masked to ensure a neat sealant line. Do not allow masking tape to touch clean surfaces to which the silicone sealant is to adhere. Tooling should be completed in one continuous stroke within 5 minutes after sealant application. Masking tape should be removed immediately after tooling.

Equipment cleaning

When not being used it is recommended that the dispensing equipment be purged either with the base component, or flushed with a suitable solvent such as DowSilTM 3522 Concentrated Cleaning Solvent. If cured sealant has built up inside the equipment, flush the equipment for the appropriate time with DowSilTM 3522 Concentrated Cleaning Solvent, using a solvent recirculation system. This solvent dissolves cured silicone sealant and provides optimum cleaning performance.

How to Use

DowSilTM 993 Structural Glazing Sealant offers unprimed adhesion to most coated and uncoated glasses as well as most metal spacers. The sealant is compatible with DowSilTM Neutral Curing Construction Sealants such as DowSilTM 791 Silicone Weatherproofing Sealant, and DowSilTM Neutral Curing Insulating Glass Sealants such as DowSilTM 3362 HD Insulating Glass Sealant, as well as most commonly used glazing components. It is important when selecting components for a project that adhesion and compatibility tests are carried out, and found to be successful, before the project starts.

Mixing and dispensing

To obtain the ultimate physical properties from DowSilTM 993 Structural Glazing Sealant it is recommended that the base and curing agent are thoroughly mixed using an airless mixing system found on most existing commercially available two-part silicone dispensing machines. Only special, two part hand mixed cartridge systems endorsed by Dow Corning® should be used to avoid incorporation of air into the material.

DowSilTM 993 Structural Glazing Sealant should be mixed in a ratio of 10:1 base to curing agent by weight, or equivalent 7.8:1 by volume for optimal properties. At this mix ratio, the sealant typically exhibits a working time of 10-30 minutes and allows units to be handled within two hours. Small variations in mixing ratio can be tolerated, but these should not exceed 11:1 to 9:1 by weight or 8.9:1 to 7.3:1 by volume to ensure minimum properties are obtained.

Lot matching of DowSilTM 993 Base and DowSilTM 993 Curing Agent is not required. Before use it is recommended that the curing agent be stirred to ensure homogeneity of all components. DowSilTM 993 Curing Agent will react with atmospheric moisture and therefore should not be exposed to air for prolonged periods of time.

Different catalysts are available for DowSilTM 993 Structural Glazing Sealant:

DowSilTM 993 Structural Glazing Catalyst is a medium viscosity paste, fast cure, which is suitable for meter mix equipment using a pressure pot or follower plate system for the catalyst.

DowSilTM 993 HV/GER Structural Glazing Catalyst is a viscous paste, fast cure, which is suitable for meter mix equipment that uses a follower plate system for the catalyst.

Preparatory work

Clean all joints and glazing pockets, removing all foreign matter and contaminants such as grease, oil, dust, water, frost, surface dirt, old sealants, or glazing compounds and protective coatings.

Metal, glass and plastic surfaces should be cleaned by mechanical or solvent procedures. Where used, solvent should be wiped on and off with clean, oil- and lint-free cloths.

Priming

Priming is not usually required when using DowSilTM 993 Structural Glazing Sealant. However, it is essential that adhesion be tested prior to use. Specific primer recommendations will be made by Dow Corning Technical Services Department on a project basis. Please contact Dow Corning for further advice.

Masking and tooling

Areas adjacent to joints may be masked to ensure a neat sealant line. Do not allow masking tape to touch clean surfaces to which the silicone sealant is to adhere. Tooling should be completed in one continuous stroke within 5 minutes after sealant application. Masking tape should be removed immediately after tooling.

Equipment cleaning

When not being used it is recommended that the dispensing equipment be purged either with the base component, or flushed with a suitable solvent such as DowSilTM 3522 Concentrated Cleaning Solvent. If cured sealant has built up inside the equipment, flush the equipment for the appropriate time with DowSilTM 3522 Concentrated Cleaning Solvent, using a solvent recirculation system. This solvent dissolves cured silicone sealant and provides optimum cleaning performance.

Maintenance

No maintenance is needed. If sealant becomes damaged, replace damaged portion. DowSilTM 993 Structural Glazing Sealant will adhere to compatible cured silicone sealant which exhibits a clean knife-cut or abraded surface.

Technical Services

www.abe.co.za

Handling Precautions

PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND MATERIAL SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE MATERIAL SAFETY DATA SHEET IS AVAILABLE ON THE DOW CORNING WEBSITE AT DOW CORNING.COM, OR FROM YOUR DOW CORNING SALES APPLICATION ENGINEER, OR DISTRIBUTOR, OR BY CALLING DOW CORNING CUSTOMER SERVICE.

Usable Life & Storage

When stored at or below 30ºC, DowSilTM 993 Curing Agent has a usable life of 14 months from the date of production.

When stored at or below 30ºC, DowSilTM 993 Base has a usable life of 14 months from the date of production.

Packaging Information

DowSilTM 993 Base is available in 250 kg drums and 20 liter pails.

DowSilTM 993 Curing Agent is available in 25 kg pails.

Beside black and clear, the curing agent is offered in a variety of gray shades. Custom colors may be available on request.

Please refer to our color card (ref. 62-1633).

Limitations

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.

Health & Environmental Information

To support Customers in their product safety needs, DowSilTM has an extensive Product Stewardship organization and a team of Product Safety and Regulatory Compliance (PS&RC) specialists available in each area.

For further information, please see our website, consumer.dow.com or consult your local Dow Corning representative.

Limited Warranty Information – Please read carefully

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customer’s tests to ensure that our products are safe, effective, and fully satisfactory for the intended end use. Suggestions of use shall not be taken as inducements to infringe any patent.

DowSilTM’s sole warranty is that our products will meet the sales specifications in effect at the time of shipment.

Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted.

DOWSIL SPECIFICALLY DISCLAIMS ANY OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY.

DOWSIL DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

We help you invent the future.™

consumer.dow.com

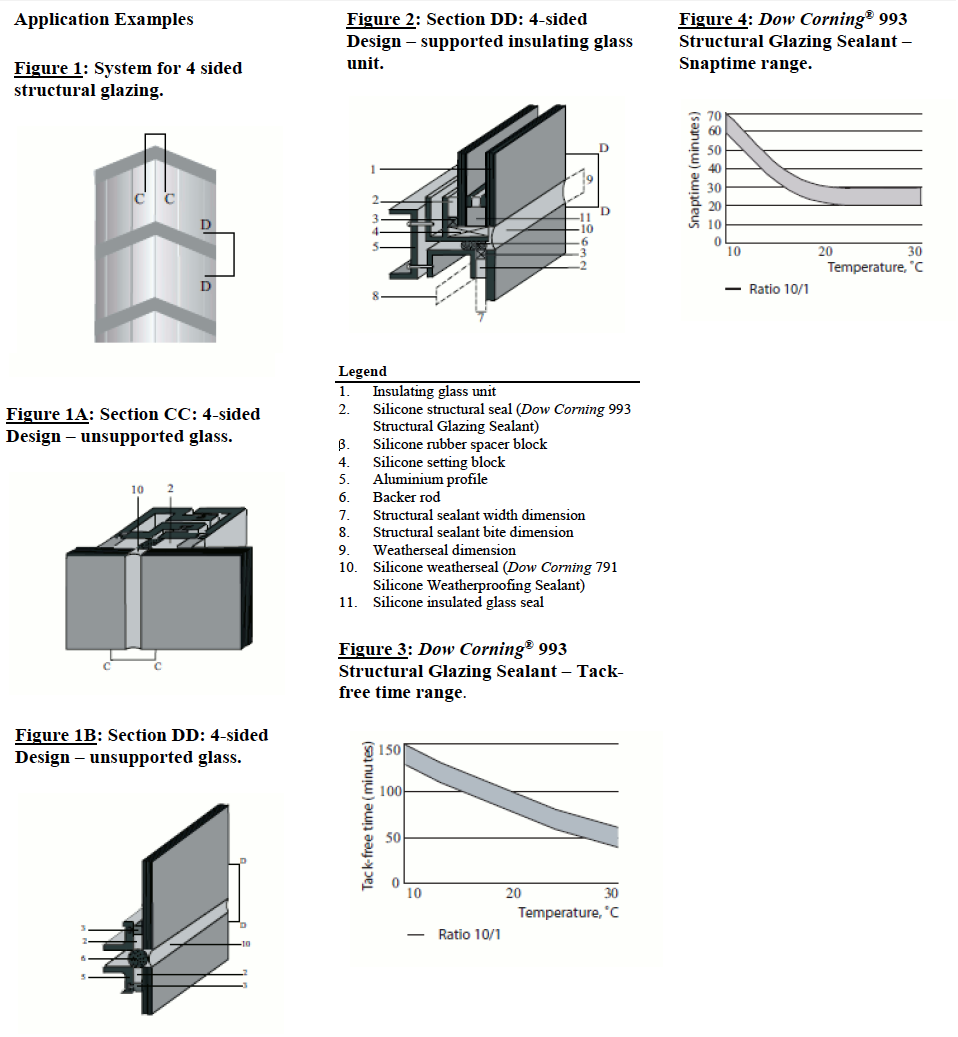

Application Examples