Insulated glazing sealant for structural glazing

Two-part silicone sealant for use as secondary sealant in insulating glass units

Features & Benefits

- When used correctly, manufactured dual sealed insulating glass units meet EN1279 and CEKAL requirements.

- Outstanding adhesion to a wide range of substrates including coated and reflective glasses, aluminum and steel spacers, and a variety of plastics.

- Structural capability as secondary sealant for insulating glass units used in structural glazing.

- CE Marked according to ETAG 002.

- Meets sealant requirements according to EN 1279 parts 4 and 6 and EN 13022.

- Low water absorption.

- Excellent temperature stability: -50 °C to 150 °C.

- Very high modulus which limits the stress on the primary sealant and makes it particularly suited for gas-filled insulating glazing units.

- Non-corrosive cure.

- Fast curing time.

- Outstanding resistance to ozone and ultraviolet (UV) radiation.

- Stable viscosity for A and B components, no heating required.

Applications

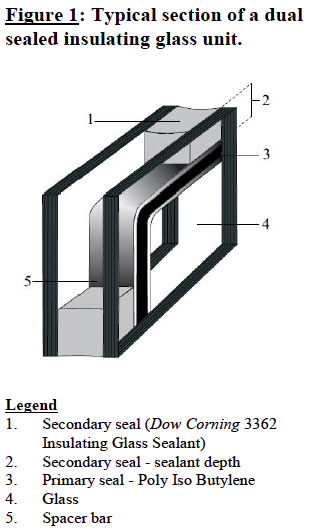

- DowSilTM 3362 HD Insulating Glass Sealant is intended for use as a secondary sealant in a dual sealed insulating glass unit.

- The high performance features incorporated into this product make it especially suitable for the following applications:

- Insulating glass units for residential and commercial use.

- Insulating glass units with high levels of UV exposure (free edge, green house, etc.).

- Insulating glass units incorporating specialty glass types.

- Insulating glass units where high heat or humidity may be encountered.

- Insulating glass in cold climates.

- Insulating glass units used in structural glazing.

- Insulating glass units where a high modulus secondary sealant is required, e.g. to limit stress onto the primary sealant for noble gas-filled insulating glazing units.

Typical Properties

DowSilTM 3362 HD Insulating Glass Sealant has been extensively tested under different type of glass and conditions (air permeability, gas, etc.).

For further information please contact our Technical services department.

Description

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total requirements. a.b.e.® has a wealth of technical and practical experience built up over years in the company’s pursuit of excellence in building and construction technology.

Technical Specifications and Standards

DowSilTM 3362 HD Insulating Glass Sealant is recommended for use as secondary seal in gas-filled insulating glass units meeting requirements according to EN1279 in an IG system. It is suitable for double and triple IG. As valid for any other technology, a proper application and fabrication of the Insulating glass unit is required.

DowSilTM 3362 HD sealant has the CE Mark according to ETAG 002. The product also meets sealant requirement according to EN1279 parts 4 and 6.

DowSilTM 3362 HD sealant has the SNJF Vi-VEC label.

How to Use

Mixing and dispensing instructions

DowSilTM 3362 HD Insulating Glass Sealant should be mixed in a ratio of 10:1 base to curing agent by weight. At this mix ratio, the sealant typically exhibits a working time of 5-10 minutes and allows units to be handled within two hours. Slight variations in mixing ratio can be tolerated, but these should not exceed 12:1 to 9:1 by weight to ensure minimum properties are obtained.

The sealant is compatible with most of DOWSIL® Neutral Curing Sealants. Please contact our Technical Services Department for more information.

To obtain the best mechanical properties from DowSilTM 3362 HD Insulating Sealant it is recommended that the base and curing agent are thoroughly mixed using an airless mixing system found on most existing commercially available two-part silicone dispensing machines.

Equipment cleaning

When not being used it is recommended that the dispensing equipment be purged either with the uncatalyzed base, or flushed with a suitable solvent such as DowSilTM 3522 Concentrated Cleaning Solvent. If cured sealant has built up inside the equipment it is recommended to flush the equipment for the appropriate time with DowSilTM 3522 Concentrated Cleaning Solvent. This solvent dissolves cured silicone sealant and provides optimum cleaning performance.

Technical Services

DowSilTM provides comprehensive technical service as part of customer support to ensure the optimal performance of your insulated glass design. This includes dispensing equipment recommenda-tions, as well as sealant compatibility testing with all your chosen insulated glass unit components. For structural glazing applications, special unit design should be reviewed on a project basis by Dow Corning technical service staff.

Consult DowSilTM’s Technical Services departments for further advice on specific applications:

www. www.abe.co.za

Handling Precautions

PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND MATERIAL SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE MATERIAL SAFETY DATA SHEET IS AVAILABLE ON THE DOW CORNING WEB SITE AT DOW CORNING.COM, OR FROM YOUR DOW CORNING SALES APPLICATION ENGINEER, OR DISTRIBUTOR, OR BY CALLING DOW CORNING CUSTOMER SERVICE.

Usable Life & Storage

When stored at or below 30°C, DowSilTM 3362 HD Insulating Glass Curing Agent has a usable life of 14 months from the date of production.

When stored at or below 30°C, DowSilTM 3362 HD Insulating Glass Base has a usable life of 14 months from the date of production.

Packaging Information

Lot matching of Base and Curing Agent is not required.

DowSilTM 3362 HD Insulating Glass Base is available in 250kg drums and 20 liter pails.

DowSilTM 3362 HD Insulating Glass Catalyst is available in 25kg pails.

Limitations

The sealant cannot be used for structural glazing of glass units onto a metal frame. Dowsil® 993 Structural Glazing Sealant is the recommended product for that application.

Please contact DowSilTM to get the proper glazing recommendations when use of Coated Glass.

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.

Health & Environmental Information

To support Customers in their product safety needs, DowSilTM has an extensive Product Stewardship organization and a team of Product Safety and Regulatory Compliance (PS&RC) specialists available in each area.

For further information, please see our website, consumer.dow.com or consult your local Dow Corning representative.

Limited Warranty Information – Please read Carefully

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customer’s tests to ensure that our products are safe, effective, and fully satisfactory for the intended end use. Suggestions of use shall not be taken as inducements to infringe any patent.

DowSilTM’s sole warranty is that our products will meet the sales specifications in effect at the time of shipment.

Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted.

DowSilTM SPECIFICALLY DISCLAIMS ANY OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY.

DowSilTM DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

We help you invent the future.™

consumer.dow.com

Illustrations