Rapid fixing mortar for concrete floors

aberep FS is a single component, rapid fix cementitious mortar used to patch holes in concrete floors.

Uses:

aberep FS is particularly useful for smaller patch type repairs to concrete floors offering a minimal amount of downtime. aberep FS can be used to fill holes in concrete floors prior to the application of self-levelling underlayments and/or screeds.

REPAIR

REDUCE

PRIME

aberep FS (Fast Setting)

Advantages

- Ready-to-use, only add clean water

- Dustless, >80% reduction in the dust during handling and mixing

- The chemical action of the product is specially formulated to be fast acting, permitting completion of patching in hours

- Chloride free

- Constant quality/performance (pre-blended)

- Non-toxic

Typical Properties

| TYPICAL PROPERTIES | |

| Water content | 4.60 L/20 kg |

| Open time (20°C) | 30 minutes |

| Drop table flow ASTM C230 | ≈200 mm |

| Initial set ASTM C807 | 40 – 45 min. |

| Final set ASTM C807 | 50 – 60 min. |

| Fresh wet density | ≈1800 kg/m³ |

| Compressive strengths – MPa – (ASTM C 109) | |

| 1 day | 10 |

| 3 days | 15 |

| 7 days | 20 |

| 28 days | 30 |

Surface Preparation

The substrate must be sound, firm, clean, and free of oil, grease, loose particles, cement laitance, old layers of paint or other contaminants. In severe cases, chemical or steam degreasing might be required.

Ensure that the substrate is roughened to provide a sufficient mechanical key for bonding. When using compressed air for cleaning, the air must be clean and oil free.

Expose any corroded reinforcing steel and grit blast. A clean, bright finish is required ensuring that all corrosion products are removed, particularly from behind the steel.

Bonding / Priming

Absorbent substrates must be thoroughly pre-wetted with clean water to reduce suction, which causes shrinkage and poor adhesion. This must be done at least 12 hours prior to the application of aberep FS. Remove any ponded water prior to the application of aberep FS.

Prime with durabond GP (at approximately 8 m²/L) in lighter structural repairs where structural adhesion properties are not required. The product must be applied to a tacky primed surface and not dry. See the relevant data sheet.

Use epidermix 116 wet-to-dry epoxy as a primer for structural applications (high frequency foot traffic) where the bond strength must be equal or greater than the parent material. See the relevant data sheet.

All exposed reinforcing bars must be primed before initial rust starts by applying durarep ZR primer. See the relevant data sheet.

Mixing

Coverage

Application

The concrete substrate should be well dampened, with no free water on the surface.

aberep FS is used for repair and restoration of small horizontal areas such as worn, chipped or spalled concrete.

aberep FS is applied a minimum of 5 mm up to 40 mm in thickness in a single application. The product should be well compacted into position, especially around reinforcing steel, generally using a wooden float to obtain good compaction and a dense matrix.

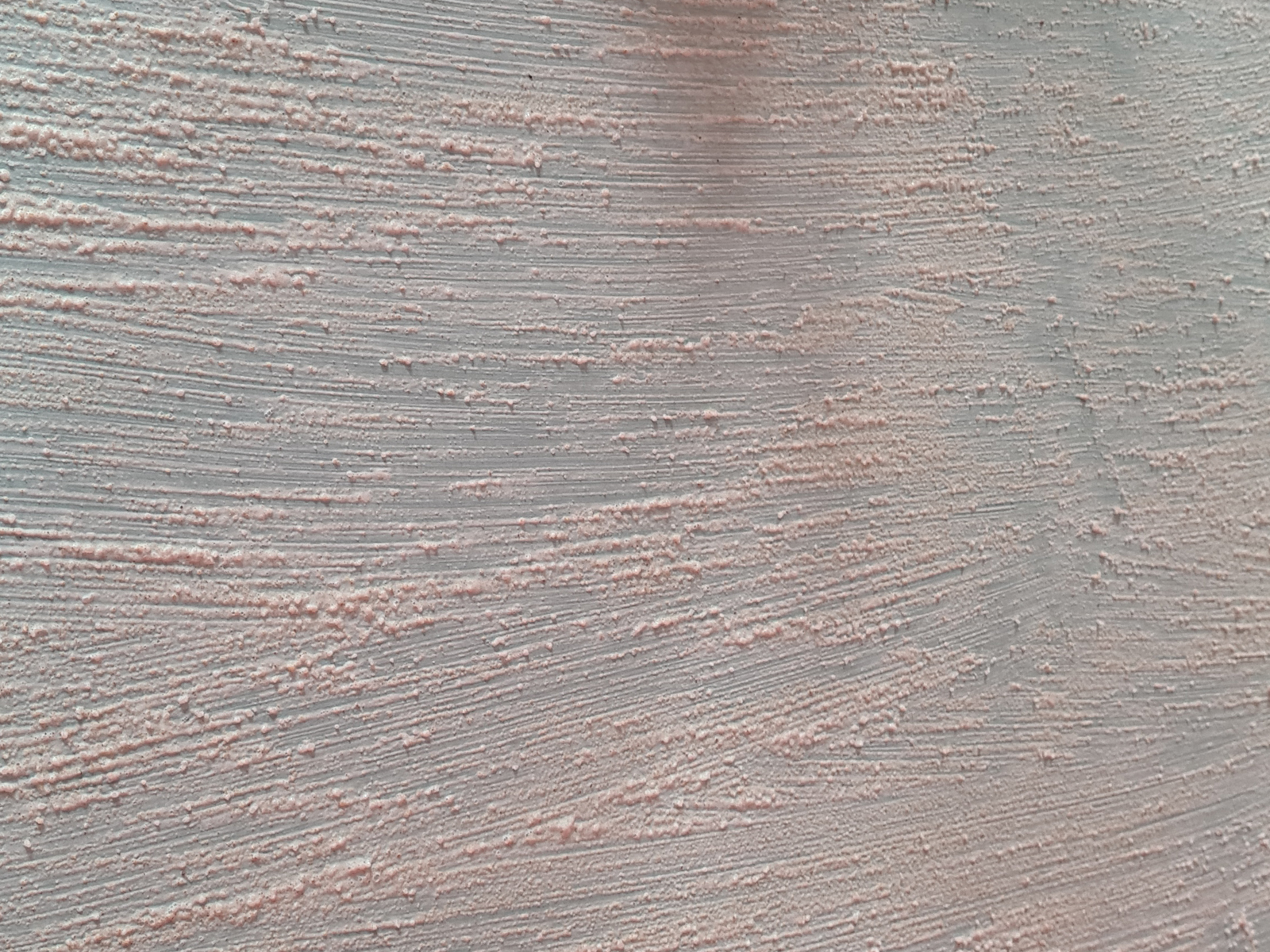

aberep FS is generally finished off to profile by using a steel float to obtain a smooth, dense, and tight surface. When other surface finishes or textures are required, a wooden float or brush can be used.

Never overwork the surface.

Cleaning

Clean tools with water before the mortar hardens. Hardened material can only be removed by mechanical means.

Protection on Completion

Temperature & Relative Humidity

Model Specification

Packaging

Handling & Storage

This product has a shelf life of 12 months if kept in a dry cool place in the original packaging. In more extreme conditions shelf life will be shortened.

Health & Safety

aberep FS is alkaline and must not be allowed in contact with skin and eyes. Avoid inhalation of dust during mixing by wearing dust masks. The use of gloves, eye protection and dust masks is advised. Immediately wash with water in the event of contact with skin.

Splashes into eyes should also be washed immediately with plenty of clean water and medical advice sought thereafter. If swallowed seek medical attention immediately without inducing vomiting.

Important Note

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total

requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction

technology.