Single component hybrid construction sealant

flexothane® 27 is a thixotropic isocyanate, VOC-free moisture-curing sealant, based on Hybrid technology. It is a filled system that offers moisture and oxidation resistance and provides good adhesion to cementitious and steel substrates.

Uses

flexothane® 27 can be used as a general joint sealer and crack filler on cementitious surfaces. It provides medium chemical, wear and corrosion resistance. A degree of colour change with time is to be expected. It is not recommended for use in water retaining structures. flexothane® 27 is selff-priming and overcoatable.

It is recommended to do a compatibility test prior to application or painting.

Advantages

- One-component, easy to gun

- Non-sag consistency

- Non-tack/does not pick up dirt

- Good adhesion properties without the use of a primer

- Over paintable with water, solvent based paints

- Good weathering and ageing properties

- Can be applied vertically or horizontally

Preparation of Joints

Thorough preparation of joints is essential if a satisfactory seal is to be obtained. For concrete, stone, or masonry surfaces, all traces of dust, laitance, mould release oil and dry. The previous sealants and all other foreign materials must be removed by sandblasting or mechanical abrasion, followed by blowing out the joints with dry, oil free compressed air. For glass, metal, and other non-porous surfaces, ensure these are free of coatings, oils, and grease by cleaning with a suitable solvent. Suitable solvents include abe® thinners no. 3, IPA, or MEK. Ensure the solvent is compatible with the substrate prior to cleaning.

Typical Physical Properties of Cured Material

| 100% Modulus (MPa) | 0.25 – 0.40 |

| Tensile strength (MPa) | 0.80 – 1.50 |

| Elongation at break (%) | >600 |

| Shore A | 25 ± 5 |

| TVOC | Complies |

| Density | 1.4 (Cured) |

***Download the technical datasheet for a full list of typical physical properties.

Priming of Joints

flexothane® 27 generally has good adhesion properties without the use of a primer on most common building substrates. However, it is advisable to do a preliminary check to ensure adhesion to the substrate.

If applied to natural stone, we recommend the use of flexoprime® 105 Primer.

The primer film should be allowed to lose its solvent before sealant is applied.

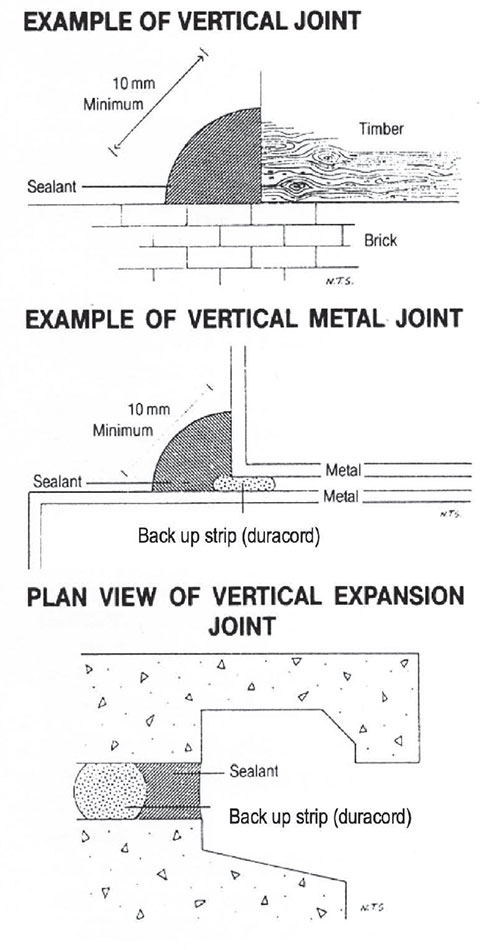

Fillets

Where a triangular pointing fillet cannot be avoided, the fillet must be applied such that it is not less than 10 mm across the face and with a rounded (convex) surface. Where there is a gap greater than 5 mm between the adjoining surfaces, a back-up material must be inserted, and the sealant applied in a sufficiently large fillet to ensure adequate adhesion area on each surface.

Back-Up Material

Suitable backup materials must be used to adjust sealant depth in the joint such as duracord (a closed cell polyethylene cord).

Protection of Adjacent Surfaces

Masking tape applied to areas adjacent to the joint will protect them from contamination and enable the joints to be finished in a neat line. The tape should be applied after the joint has been prepared, prior to any priming or sealing operation and removed after all finishing and tooling operations have been completed, but before the sealant has cured.

Coverage

Theoretical Coverage for Estimating Purposes

| Joint Dimensions (mm) | Metres per 600 ml sausage |

| 20 x 12 | 2.50 |

| 12 x 12 | 4.17 |

| 6 x 6 | 16.67 |

Application

Place sausage in the barrel gun cut the end off the sausage, and fit the nozzle; trim the tip to suit the joint spacing to be filled. Insert backing rod to the correct depth. Gun the product into clean joints that are free of loose material and laitence, then smooth with a dry spatula. The joint width should be designed to accommodate the expected movement, width to depth ratio of 2:1 should be respected and a minimum width of 6 mm and a maximum of 20 mm should be adhered to. Backing cord/Bond Breaker should be used depending on the application, to prevent three-sided adhesion.

Tooling

Tooling of sealants is necessary for complete air-free filling of voids and to assist in making contact to the surfaces to which the sealant is applied. The surfaces of the joint should be smoothed with a clean putty knife or spatula.

Mixing

Not required.

Painting over Sealant

It is not recommended that a flexible sealant be over-coated by less flexible coatings as joint movement will cause rupturing of the coating. Also, plasticisor migration from the sealant into the coating could result in excessive dirt pick-up. Based on the outcome of preliminary tests the sealant may be over painted with a good quality water or solvent based paint.

Cleaning

Tools should be cleaned immediately after use, and before the material has cured, with abe® super brush cleaner followed by washing with soap and water.

Model Specification

The one part polyurethane construction sealant will be flexothane® 27 a single-pack, medium modulus, moisture curing hybrid construction sealant as supplied by a.b.e.®

flexothane® 27 will be applied in accordance with the recommendations of a.b.e.®

Packaging

600 ml sausages packed 20 per box and 280 ml cartridges packed 12 per box.

Handling & Storage

This product has a shelf life of 12 months if kept in a dry cool place in the original packaging. In more extreme conditions this period might be shortened.

Health & Safety

Uncured flexothane® 27 is toxic and should not be allowed contact with skin and eyes. The use of gloves and eye protection is advised. Splashes into eyes should be washed immediately with plenty of clean water and medical advice sought. Ensure the working area is well ventilated during application and drying. Always wear gloves when working with the material and avoid excessive inhalation and skin contact.

Cured flexothane® 27 is inert and harmless.

Important Note

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or continuous control over where and how a.b.e.® products are applied.

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total

requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction

technology.