Polyurethane enamel

abecote® 441 is a protective and decorative coating for steel, concrete and timber.

Uses

Finish coating on various flooring systems, as well as on steel, concrete and timber.

Advantages

- Non-toxic when dry

- Salt spray resistance (passes 1 000 hours)

- Weather resistance – does not chalk, white does not yellow

- Excellent water resistance

- Resists aliphatic solvents, xylol, alcohol

- Does not taint water

- Good distilled water resistance

Surface Preparation

At the time of applying abecote® 441 the surface should be clean, mechanically sound and dry. abecote® 441 is normally applied over primed surfaces and therefore surface preparation must be consistent with the primer being used. If timber is sealed with abecote® 441, it should be sanded smooth and all debris of sanding removed. Oily timbers such as teak should be washed down with pure acetone (oil free acetone) and allowed to dry before coating with abecote® 441.

The substrate must be dry before application. Moisture content tests must be conducted prior to application of the priming system e.g. protimeter survey master or equivalent, or dynamic calcium chloride moisture “weight gain” over 24 hours, or a practical overnight “plastic sheet test” is also advisable approximately 1 m² masked own on surface.

Properties Of Wet Material

| Mixing ratio base: activator |

2:1 by volume |

| Density (typical) | 1.40 g/cm³ white 1.20 g/cm³ colours 1.10 g/cm³ clear |

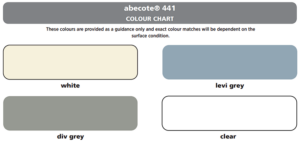

| Colour | Base: Clear or pigmented Activator: Clear Mixed material: Clear or as per abecote® colour chart |

| Finish | High gloss |

| Flash point | 17 ºC |

| Fire resistance | Flammable |

| Dilution | abe® thinners no. 2 only |

| Consistency | Low-medium viscosity liquid |

| Toxicity | Contains toxic solvents |

Properties Of Dry Film

| Maximum service temperature |

Dry ±120 ºC Immersion ±70 ºC |

| Flexibility on conical mandrel |

Passes |

| Hardness | 2 000 gm (sheen scratch test) |

| Chemical resistance | 10% hydrochloric acid, 10% phosphoric acid, 10% sulphuric acid, 40% caustic soda domestic bleach |

Properties During Application

| Pot life | 8 hrs/5 L @ 25 ºC (white) 3 hrs/5 L @ 25 ºC (clear) |

| Volume solids | 53% pigmented 38.5% clear |

| Recommended average dft per coat |

35 – 40 μm pigmented 25 μm clear |

| Theoretical coverage for above dft |

13.5 m²/L pigmented 16.5 m²/L clear on smooth surfaces |

| Wet film thickness at above coverage |

75 μm pigmented 50 μm clear |

| Maximum recommended wft |

100 μm pigmented 80 μm clear |

| Practical coverage | 6 – 9 m²/L pigmented 7 – 10 m²/L clear dependent on surface texture) |

| No. of coats | Minimum 2 |

| Drying time @ 25 ºC | Touch dry 5 hours Hard dry 12 hours Full cure 7 days |

| Overcoating time @ 25 ºC | Minimum 12 hours Maximum 48 hours |

Bonding/priming

• mild steel – abecote® 384

• dry concrete and other porous surfaces – abecote® 386 or abecote® 436

• timber (under pigmented abecote® 441) – abecote® 386 ensure the timber is free of natural oils by solvent wiping the surface with oil free acetone and allow it to dry.

• galvanised steel – abecote® 386 ensure that the surface is clean and free of oils, etc. from the galvanizing process and must provide a water break free surface.

abecote® 386 is easy to rub down with emery or sand paper and to achieve the best finish this should always be done and all resulting debris removed. If wet sanding, the surface must be allowed to dry completely as any trace of moisture under abecote® 441 will promote bubbling in the film. Where abecote® 441 clear is used on timber no priming is required.

Reduce the first coat with 15% abe® thinners no. 2.

Mixing

Stir the contents of each container, particularly the base, very well. Add activator to base and stir together for at least 5 minutes using a flat paddle. Mechanical mixing gives better dispersion than manual mixing. A suitable mixing method would be a slow speed electric drill (approximately 200 r/min) fitted with a paddle. If only part of a kit is to be used, add one volume of activator to two volumes of base. Measuring must be accurate and separate stirrers and containers used for proportioning each component.

Allow mixed material to stand for 20 minutes in shade prior to application. If thinning is needed use only abe® thinners no. 2 – incorrect choice of thinners may cause bubbling in the film. If the kit is split and kept for future use, the activator container must be very tightly sealed and stored upside down. The activator will react with moisture in the air. The split kit should not be stored for more than a few days or gelling will occur.

Application

abecote® 441 should be applied to the pre-primed surface within the overcoating time stipulated for the relevant primer.

If airless spray is used for application a nozzle of approximately 400 μm should be used. Conventional spray is not recommended since any trace of moisture in the air supply may result in bubbling. Bubbling can also result from using damp brushes or short fibre rollers which are not completely dry before use, and also from applying too thick a film of material. Never apply thicker films than recommended.

abecote® 441 should not be applied if the ambient temperature is below 8 °C. The curing reaction will not proceed at low temperatures. If the surfaces are not at least 3 °C (preferably 5 ºC) above the dew point there is every chance that a film of condensed moisture could be present. This again will cause bubbling, surface cloudiness as well as compromising adhesion.

Cleaning

abe® super brush cleaner before curing.

Protection On Completion

Protect surface against traffic and spillage until cured.

Model Specification

The coating will be abecote® 441, a two component polyurethane enamel applied in accordance with a.b.e.®’s recommendations.

Packaging

abecote® 441 is supplied in 1 L and 5 L yield metal containers.

| Clear Gloss ( IH ) | 44199055(IH) |

| Clear Matt ( IH ) | 44173005(IH) |

| White ( IH ) | 44101055(IH) |

| Div Grey (IH ) | 44172005(IH) |

| Levi Grey | 44172-005 |

| Road Marking Yellow | 44145005 |

| Road Marking Black | 44147005 |

Handling And Storage

All abecote® 441 related products have a shelf life of 12 months if kept in a dry, cool store in the original, unopened packs. If stored at high temperatures and/or high humidity conditions, the shelf-life may be reduced.

Health And Safety

Wet abecote® 441 is toxic and flammable. Ensure working area is well ventilated during application and drying. Avoid flames in vicinity. Avoid inhalation of dust and contact with skin and eyes. Suitable protective clothing, gloves, eye protection and respiratory protective equipment should be worn. The use of barrier creams provides additional skin protection. If contact with skin occurs, wash with water and soap. Splashes into eyes should be washed immediately with plenty of clean water and medical advice sought. Cured abecote® 441 is inert and harmless. When transporting liquids and semi liquids by aircraft, ask for material safety data sheet.

Important Note

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation,

specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or

continuous control over where and how a.b.e.® products are applied.

Further Information

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation,

specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or

continuous control over where and how a.b.e.® products are applied.

Color