Hi-build epoxy floor coating

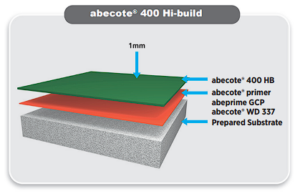

abecote® 400 Hi-build is an economical four-component, solvent-free epoxy flooring system comprising a clear resin and hardener, pre-packed filler and a ready-for-use pigment paste.

Uses

Floor coating in ablution blocks, walkways, food processing plants, hospitals and schools etc. May also be used as a binder for abrasive grit to yield non-slip floor finishes.

Advantages

- Good protective qualities

- Good resistance to chemicals

- Reduces maintenance

- Range of colours

- Can be applied onto a variety of surface

- Seamless and hygienic

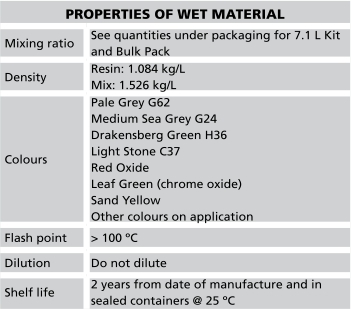

Properties of Wet Material

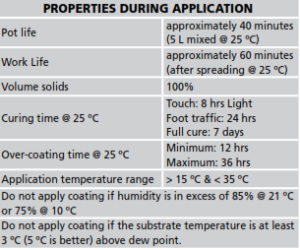

Properties During Application

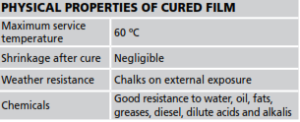

Physical Properties of Cured Film

Surface Preparation

Precautionary Notes

(1) The substrate must be dry before application. For concrete, moisture content tests must be conducted prior to application of the priming system. Maximum moisture content should be between 4 – 5% (preferably a Protimeter Survey Master or equivalent, or Dynamic).

Calcium Chloride moisture “weight gain” over 24 hours, or at least a practical overnight “plastic sheet test” is also advisable (approximately 1 m2 masked down on surface).

(2) Concrete substrate must have a minimum tensile strength of 1.5 N/mm.

Concrete shall be free of all laitance and preferably should be lightly vacuum blast cleaned leaving a uniform texture. All blemishes in the surface such as pop-outs, omegas, blowholes and honeycomb should be patched with epidermix® 201. This should be left overnight to cure and shall then be rendered smooth. For a smooth final finish, the surface profile, peak to valley, should not exceed 25% of the coating thickness. If the surface is very irregular, consideration should be given to the use of abe® prime SL, a solvent free epoxy self leveling primer.

Bonding / Priming

If abe® prime SL is not used, then abecote® 400 Hi-build is normally applied over a thoroughly sealed concrete surface using up to two coats of abecote® 337.

Over coating of the primer with abecote® 400 Hi-build should comply with the over coating time requirements laid down for the specific primer. The over coating time for abecote® WD 337 is 4 – 6 hours.

Mixing

Precautionary Notes

(1) When decanting base from bulk supply, thorough stirring must be accomplished beforehand.

(2) In order to avoid colour variation in large expanses, one must ensure that the same pigment batch is used and is carefully and accurately dispensed (factory batching available on request).

Proper mixing and proportioning of the epoxy binder (base and activator), filler and pigment is essential for good results with no colour variation from mix to mix.

Transfer pre-measured volume of flooring base resin to mixer. Add pigment and activator and homogenize. Add filler slowly and mix well.

Note:

(1) A slow speed mixer must be used. Ensure that the mixing vanes are below the surface of the mix to minimize air entrapment. The stirrer mixing vane configuration should be such as not to introduce unwanted aeration. Also, for this type of mixing, transferring the base/activator combination to a new container i.e. “re-mixing” will eliminate contamination due to unmixed base which is inclined to cling to the walls of the original container.

(2) Where light colours (yellows/white etc.) are used, the addition of 2 units of pigment pastes per kit is advised to ensure opacity. A similar coloured primer is also recommended.

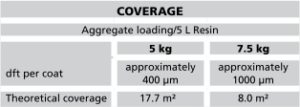

Coverage

Application

Precautionary Note

Prevailing weather conditions must be taken into account otherwise surface defects can occur (see under “properties during application”).

abecote® 400 Hi-build should be applied by first pouring a bead of material in the form of a ribbon on the surface to be coated. Do not leave material in the container too long because it will set faster thus reducing the work life. Using a serrated trowel, spread the applied material at the specified rate. Apply as evenly as is possible, working from left to right, and then back. Approximately 10 minutes after application, roll using a porcupine roller to aid in excess air release. All over-coating times must be strictly adhered to. abecote® 400 Hi-build will not cure if applied at below 10 ºC.

Non-Slip Surface

Precautionary Note

Overcoat times of 48 hours maximum must be adhered to at all stages.

A non-slip surface can be achieved by applying a clear bond coat of abecote® 400 Hi-build Resin onto the relevant cured pigmented abecote® 400 Hi-build System base coat at an approximate rate of 3 m²/L and broadcasting into this a suitable grit at the rate of approximately 50 g/m2. Ensure that grit application is evenly broadcast and back-rolled using a short mohair fibre roller.

Also see ‘Non-slip floor finishes’ literature.

Cleaning of Equipment

abe® super brush cleaner before setting.

Protection / Maintenance on Completion

Enlist the services of experienced cleaning specialists. Furthermore, the following recommendation will go a long way to maintain the original appearance of the epoxy floor viz.

(1) Protect from trafficked dirt/grit ingress into coated area by using dirt traps etc.

(2) Use of a “renewable” clear high wear polymer based floor polish will reduce scratching and “black heel”.

(3) Encourage frequent maintenance cleaning.

Model Specification

The epoxy floor system will be abecote® 400 Hi-build, a four-component, solvent-free epoxy floor system comprising resin and hardener, filler and pigment paste applied in accordance with a.b.e.®’s recommendations.

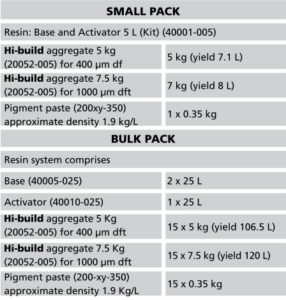

Packaging

Handling & Storage

All abecote® 400 Hi-build related products have a shelf life of 2 years if kept in a dry, cool store in the original, unopened packs. If stored at high temperatures and/or high humidity conditions, the shelf life may be reduced.

Health & Safety

Product safety information required for safe use is not included. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. The safety data sheet is available from your local a.b.e.® sales representative.

Important Note

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, the company cannot – because a.b.e.® has no direct or continuous control over where and how a.b.e.® products are applied – accept any liability either directly or indirectly arising from the use of a.b.e.® products, whether or not in accordance with any advice, specification, recommendation or information given by the company.

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total requirements. a.b.e.® has a wealth of technical and practical experience built up over years in the company’s pursuit of excellence in building and construction technology.

Colour Chart