Polyinyl Chloride

Range of externally and centrally placed waterstops

The durajoint waterstop range is extruded from specially formulated virgin PVC material, which whilst flexible is easily welded on site to provide the primary seal for expansion and construction joints in concrete cast in-situ. These joints occur in water retaining and/or water excluding structures.

Hydrostatic pressure resistance in accordance with guidelines of ASTM D 5385-93.

UV resistance in accordance with ASTM G 154-16.

Uses

The prevention of regress or ingress of water or liquids through construction or expansion joints in water retaining or excluding structures such as:

- Dams, reservoirs, digesters, water towers, canals.

- Basements, car parks, retaining walls.

Advantages

- Co-ordinated profiles

- Ensures bulb continuity throughout the network

- Making on site jointing simpler

- Allows for jointing of external to centrally placed sections

- Allows for jointing of expansion joint section to construction joint section

- Flat top to centre bulb ensures snug fit of filler board

Range

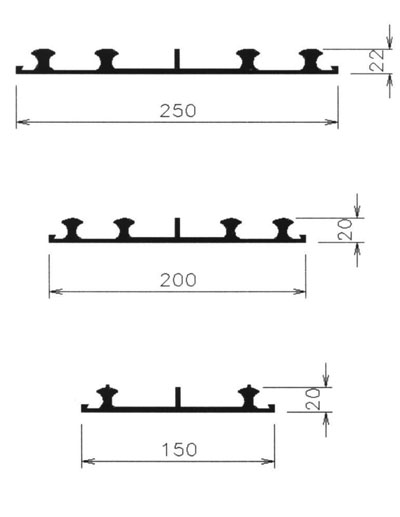

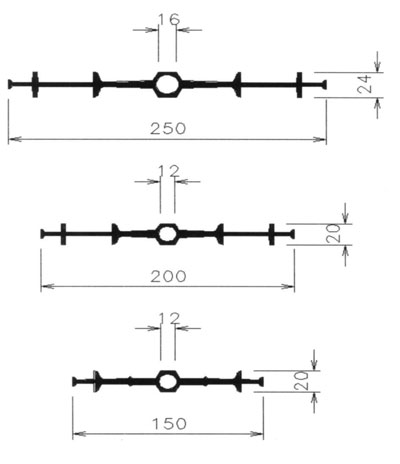

Expansion joint centrally placed

- dura.joint PVC centre bulb – 150 mm

- dura.joint PVC centre bulb – 200 mm

- dura.joint PVC centre bulb – 250 mm

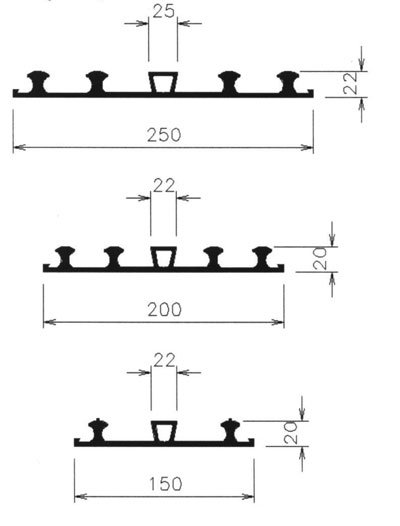

Expansion joint externally placed

- dura.joint PVC external E – 150 mm

- dura.joint PVC external E – 200 mm

- dura.joint PVC external E – 250 mm

Construction joint centrally placed

- dura.joint PVC dumbell – 150 mm

- dura.joint PVC dumbell – 200 mm

- dura.joint PVC dumbell – 250 mm

Construction joint externally placed

- dura.joint PVC external C – 150 mm

- dura.joint PVC external C – 200 mm

- dura.joint PVC external C – 250 mm

In addition, factory made intersections are available for the full range:

– Mitre on flat

– 3-way on flat

– 4-way on flat

– T-piece

– 90º on edge

– 270º on edge

All these sections can be made for both similar and dissimilar sections. All intersections should be factory produced by a.b.e.® Construction Chemicals to minimize site joints.

Physical Properties

| Form | Extruded thermoplastic PVC sections |

| Colour | Blue |

| Joint movement | Up to 10 mm |

| Hydrostatic head | 50 metres |

| Tensile strength | > 12 MPa |

| Elongation at break | > 266% |

| Shore A ASTM 2240-05 | 88 |

| Relative Density g/cm3 | 1.494 |

| Water absorption is depend on rigid/flexible/filled systems but typically ranges by weight |

from 0.15 – 1.00% |

| Alkali resistance | Good |

| Impact resistance will depend on rigid/flexible/filled systems |

In general the impact resistance is accepted to be good |

Design Criteria

The choice of the width and thickness of waterstop is largely governed by concrete thickness, the position of the reinforcement, aggregate size and complexity of the pour. In general the 250 mm width of waterstop is suited to wall thicknesses of 250 mm and over. For concrete less than 250 mm thick, the use of a narrower waterstop approximating to the wall thickness will be appropriate. 150mm and 200mm profiles are available for this purpose.

Installation Techniques

Centrally placed waterstops

durajoint CB and dumbell (DB) – are to be fully tied to the re-bar to eliminate possible displacement during the concreting and vibrating process. It is imperative that care is taken to fully compact the concrete around the waterstop in order to eliminate any voids or honeycombing in that area.

Externally placed waterstops

When used on ground slabs where the waterstop is supported on blinding, durajoint external E and external C profiles usually require no fixing. Lay the waterstop centrally over the line of the joint to be formed.

Fixing to vertical shuttering is done by nailing through the outer nailing flanges leaving the head of the nail proud so that it is held in the cured concrete. This prevents the waterstop being displaced when the shuttering is struck. (Refer diagram: Fixing externally placed waterstops to vertical shuttering)

Site Jointing

Only butt joints should be welded on site using a.b.e.® Heat Welding Equipment. Special function-made intersections are available from a.b.e.®.

The ends of the butt joints must be cut square. These cut ends should then be pushed against the preheated heater blade (supplied by a.b.e.®) until a molten bead appears against the blade. Remove the blade and firmly press the two molten ends of the waterstop together and hold firmly until these ends are fused together. A piece of shutterboard or similar material placed under the joint prior to the operation will facilitate the jointing. This jointing must be undertaken

in a well-ventilated area as the fumes given off when the PVC is being melted are an irritant to the lungs and eyes. In enclosed areas forced ventilation is a prerequisite. A wire brush is used to clean the PVC residue on the heater blade after every jointing operation.

Model Specification

ASTM D 5385-93 and ASTM G 154-16 certification available on request.

Waterstop durajoint external C

Externally placed waterstop for construction and contraction joints in walls and floors to water retaining and water excluding structures. The waterstop will be durajoint external C, an externally placed extruded plasticized PVC compound applied in accordance with the recommendations of a.b.e.®

The waterstop will comply with the requirements of CKS 389:1973 and have an elongation at break of 300%

Waterstop durajoint dumbell

A centrally placed waterstop for construction and contraction joints in walls and floors to water retaining and water excluding structures. The waterstop will be durajoint dumbell, a centrally placed extruded plasticized PVC compound applied in accordance with the recommendations of a.b.e.®

The waterstop will comply with the requirements of CKS 389:1973 and have an elongation at break of 300%.

Waterstop durajoint external E

Externally placed waterstop for expansion joints in walls and floors to water retaining / water excluding structures. The waterstop will be durajoint external E, an externally placed extruded plasticized PVC compound applied in accordance with the recommendations of a.b.e.®

The waterstop will comply with the requirements of CKS 389:1973 and have an elongation at break of 300%.

Waterstop durajoint centre bulb

Centrally placed waterstop for expansion joints in walls and floors to water retaining and water excluding structures. The waterstop will be durajoint centre bulb, an externally placed extruded plasticized PVC compound applied in accordance with the recommendations of a.b.e.®

Health & Safety

Always carry out the jointing of durajoint PVC waterstops in a well ventilated area as the fumes given off are an irritant to both eyes and lungs. In confined areas forced ventilation is a prerequisite.

Important Note

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or continuous control over where and how a.b.e.® products are applied.

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total

requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction

technology.

Estimating

| ESTIMATING | Section width | Approximate mass per roll | Minimum radii on flat | Minimum radii on edge | Roll length |

| durajoint | mm | kg | m | m | m |

| durajoint CB | 250 | 32,2 | 15 | 0,15 | 15 |

| durajoint CB | 200 | 25,8 | 14 | 0,15 | 15 |

| durajoint CB | 150 | 39,6 | 12 | 0,075 | 30 |

| durajoint dumbell | 250 | 30,8 | 15 | 0,15 | 15 |

| durajoint dumbell | 200 | 24,8 | 14 | 0,15 | 15 |

| durajoint dumbell | 150 | 36,8 | 12 | 0,075 | 30 |

| durajoint external C | 250 | 35,5 | 10 | 0,15 | 15 |

| durajoint external C | 200 | 27,8 | 9 | 0,15 | 15 |

| durajoint external C | 150 | 39,5 | 8 | 0,075 | 30 |

| durajoint external E | 250 | 38,7 | 10 | 5,0 | 15 |

| durajoint external E | 200 | 30,4 | 9 | 5,0 | 15 |

| durajoint external E | 150 | 43,4 | 8 | 5,0 | 30 |

| durajoint CB10 | 250 | 65,3 | 15 | 0,23 | 15 |

Standard Profiles

Standard Intersections

Download datasheet to view standard intersections.