Closed cell polyethylene joint formers & back up material

duracord and durasheet are manufactured from low density, closed cell expanded polyethylene. They are highly flexible and compressible, with excellent recovery properties and tensile strength.

duracord: back up material is supplied in various diameters.

durasheet: permanent, preformed bond breaker and joint former.

Uses

duracord and durasheet are semi-rigid joint fillers used for forming expansion joints or as a backing material for joints in:

- Concrete

- Brickwork

- Blockwork

- Retaining walls

- Deck slabs

- Reservoirs

- Paving

- Columns

durasheet 100 is suitable for use in water retaining structures and conforms to the requirements of a.b.e.® ’ specifications for the sealing of water retaining structures.

Advantages

- Rot proof

- Fine closed cell structure

- Non-absorbent

- Resilient

- Low load transfer

- Bitumen free

- Non-tainting

- Ozone friendly and recyclable

- Good thermal properties

Installation

duracord should be compressed into the joint to approximately 70% of its original size. Where hydrostatic pressures are present, compression should be to approximately 40% of its original size.

For most effective results, duracord must be inserted into the joint to a depth that will accommodate the depth of sealant specified i.e. joints from 6mm to 12mm wide, width and depth must be equal. From 12mm wide to 24mm wide the depth should be 12mm, and for joints over 24mm wide the depth should be half width.

In order to prevent movement of the durasheet when installing in expansion joints between suspended slabs use partly projecting copper nails or daubs of adhesive.

When forming expansion joints with durasheet in in-situ concrete joint sealing slots can be formed by first cutting through the durasheet to the required depth and pinning the strip back on to the remaining durasheet with 50mm panel pins installing the filler flush with the concrete surface. Prior to sealing remove the top strip to provide a clean joint ready for preparation of the joint sealant installation.

Bond breakers are not required as elastomeric sealants will not bond to the duracord and closed cell side of durasheet. A pvc tape should be applied to top of durasheet to avoid adhesion of sealant to open cell structure.

Design Criteria

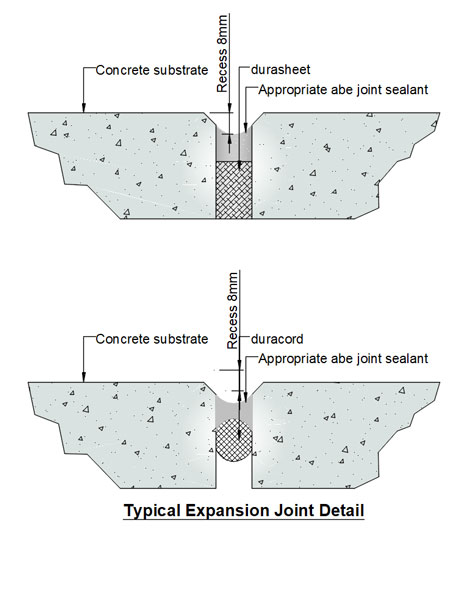

Typical movement joint

Technical Data

| TECHNICAL DATA | ||||

| TYPICAL PROPERTIES | ||||

| durasheet | Unit | 40 | Test | 100 |

| Nominal Density (kg/m3) | kg/m3 | 43 | ISO 845:2006 | 241 |

| Compression set | % | 49,5 | ISO 1856:2000 | 32,4 |

| Tensile strength @ peak | kPa | 396 | ISO 1798:2008 | 1199 |

| Tensile elongation | % | 70,4 | ISO 1798:2008 | 57,4 |

| Colour | Blue | Black | ||

| Service temperature | -40 ºC to +90 ºC | |||

| Chemical resistance | Resistant to acids and alkalis. Good resistance to oils, petrol, diesel fuel and solvents | |||

| Toxicity | Non-toxic (inert) and has no rodent attraction | |||

| Flexibility | Good to -40 (sup>oC | |||

| Composition | Closed cell expanded polyethylene |

Model Specification

duracord

Closed-cell polyethylene backing cord for filling and dimensioning joints prior to sealing with an appropriate flexible sealant.

The backing cord will be duracord, a closed-cell polyethylene backing cord applied in accordance with the recommendations of a.b.e.®

durasheet 40

Non-absorbent, closed-cell polyethylene joint filler. Used as an expansion joint former for paving, pooldecks, between columns and brickwork, walls and floors in in-situ cast concrete not subject to hydrostatic pressures.

durasheet 100

Non-absorbent, closed-cell polyethylene joint filler. Used as an expansion joint former for reservoirs, water retention works and sewage works.

Packaging

duracord is supplied in 100 metre continuous rolls in various diameters from 6mm to 50mm.

durasheet is supplied rectangular sections of 1.2 m x 2.4 m in various thicknesses from 6 mm to 50 mm. Where continuous lengths are required, the supplied lengths are easily joined using a good neoprene contact adhesive.

Handling & Storage

This product has a shelf life of 12 months if kept in a dry cool place in the original packaging. In more extreme conditions this period might be shortened.

Health & Safety

In the event of a fire care should be taken not to inhale the fumes of burning duracord or durasheet.

Important Note

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction technology.