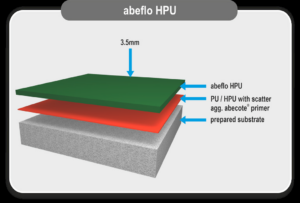

Medium duty 2,5 – 4mm self smoothing polyurethane floor screed

abeflo HPU is a medium duty flow applied polyurethane topping based on a 4 part, liquid polyurethane resin system incorporating antimicrobial silver ion protection. A textured, smooth aggregate surface of uniform colour designed for excellent resistance to abrasion, chemical attack and other physical aggression for light to medium traffic.

Advantages

- Contains silver ion technology for antimicrobial protection

- Easy to clean and sanitize due to seamless flooring

- Heat resistant to 80 °C

- High chemical, abrasion and impact resistance

- Non-slip matt finish

- Solvent free application

- Low VOC content

- Fast installation easy to use fluid consistency with excellent adhesion

Uses

- Chemical processing plants

- Food processing plants with antimicrobial additive based on silver ion technology making abeflo HPU ideal for use in HACCP environments as it provides a seamless, antimicrobial, matt finish that imparts no chemical contaminants to foods

- Breweries

- Engineering areas

Technical Details

| Technical Details | ||

| Compressive Strength | 55 N/mm2 | |

| Tensile Strength | 6.5 N/mm2 | |

| Flexural Strength | 40 N/mm2 | |

| Colours | Please refer to chart | |

| VOC | 8 g/ℓt | |

| Water Absorption | <0.2% | |

| Elastic Mod. | 1350 N/mm2 | |

| Impact Resistance | Drop Test <3 mm | |

| Heavy traffic | 24 hours | |

| Light traffic | 12-16 hours | |

| Abrasion Resistance | Accelerated <0.03 mm | |

| Chemical Resistance | Acids and sugars | |

| Kit yield | 9.67 ℓ or 10,84 ℓ | |

| Nominal thickness 2.5 mm | 3.87 m²/kit | |

| Nominal thickness 4.0 mm | 2.71 m²/kit | |

Watch Points

Prime concrete surfaces with PU HPU primer plus scattered aggregate. Application conditions should be between 10 °C and 25 °C with a maximum relative humidity of 75%.

Shelf Life

Six months when kept in a cool, dry place. Packaging must remain unopened.

Packaging

2.5 – 3 mm System:

2.6 kg Resin (Code 52512BO 026)

2.5 kg Hardener (Code 52513BO 025)

12.5 kg Aggregate (Code C52510BO 125)

Pigment (see colours)

Total kit 17.9 kg (yields 9.67 litres incl. primer)

3 – 4 mm System:

2.6 kg Resin (Code 52512BO 026)

2.5 kg Hardener (Code 52513BO 025)

15.5 kg Aggregate (Code C52510BO 155)

Pigment (see colours)

Total kit 20.9 kg (yields 10.84 litres incl. primer)

PU/HPU primer (2 part):

2.5 kg Resin White (Code B52200BO 026)

2.5 kg Hardener White (Code A49501BO 025)

5 kg Aggregate (Code C52200BO 005)

Silica sand No.2 fine 0.5 kg to 1.0 kg/m2 (Code 36503 049)

Directions

Substrate Requirements

Concrete substrates are to be 20-25 MPa compressive strength and 1.5 MPa tensile adhesion strength, free of dust and friable materials. There must be no moisture vapour rising from the concrete and moisture content must be less than 5%.

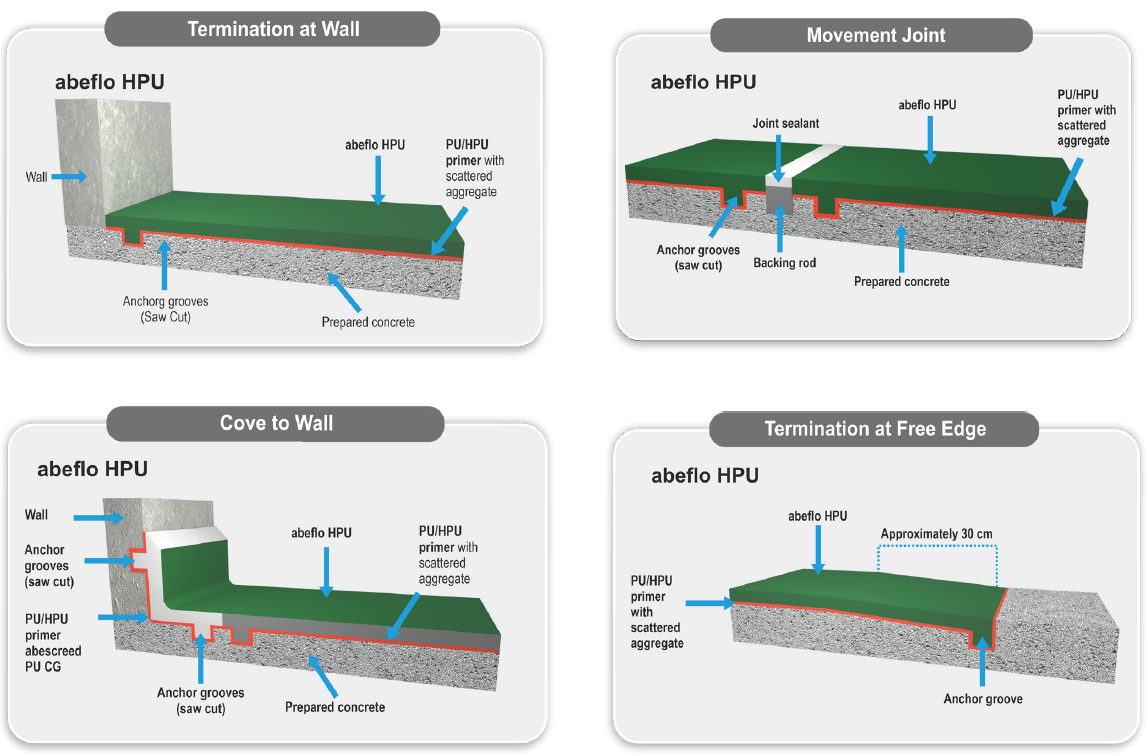

Totally enclosed heavy shot blasting or scarification should be used to remove all residues to provide a dry, dust free open textured surface with exposed aggregate. Anchor grooves, minimum 4 mm wide x 4 mm deep, must be formed at all edges, bay joints, columns doorways, drains and at regular centres across the floor. Generally, groove width and depth is twice the screed thickness. If time constraints (or any other) results in application of screed short of these anchor groves, then cut new groves to finish off application and start next application with new groves.

System

1. Concrete Primer – PU/HPU primer + Silica sand No.2 fine

2. Polyurethane topping – abeflo HPU

Application

Prepare surfaces in order to obtain a sound, dust free, dry surface. Prime with PU/HPU primer + scattered aggregate and allow to cure for at least 24 hours prior to application of abeflo HPU with a maximum overcoating time of 48 hours. Ensure application conditions are between 10 – 25 °C and at a maximum of 75% relative humidity.

Before mixing, turn the resin bottle upside down and shake vigorously to re-suspend any sedimentation. Mix the shaken resin and hardener in a pan mixer well. Then add the aggregate and, after the last of the aggregate has been added, mix until uniformly wetted out. Pour out the mix onto the demarcated area and trowel out into place. Spike roll out trowel marks and allow to settle.

Coving

Use the relevant abescreed PU CG coving grade colour with appropriate primer for coving and/or vertical applications.

Maintenance

Cleaning

Regular scrubbing and mopping will maintain the abeflo HPU in a serviceable condition.

Antimicrobial Resistance

The abeflo HPU makes use of silver ion technology in formulation which inhibits the growth of bacteria and fungi in contact with the product. The hygienic advantage is therefore not only derived from the daily use of the floor but in the longer life this technology affords in retarding the degradation of the floor by micro-organisms.

Colour Stability

abeflo HPU is not colour fast and will change in colour over time, especially when subject to direct sunlight and high intensity lighting. The rate of colour change is unpredictable.

Sealing

Stain resistance is enhanced if the abeflo HPU surface is sealed.

Storage

Store the kit in a cool, dry place out of direct sunlight and where there is no exposure to damp and humidity.

Health & Safety

Please read Material Safety Data Sheet and specific health and safety data for this product provided in compliance with the requirements of OHSA No. 85 of 1993. The finished system is not hazardous to health.

Important Note

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or continuous control over where and how a.b.e.® products are applied.

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total

requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction

technology.

Diagrams

abeflo HPU

DIAGRAMS

Colour Chart

abeflo HPU

COLOUR CHART

These colours are provided as a guidance only and exact colour matches will be dependent on the surface condition.

COLOURS

| 300 GRAM LIQUID PIGMENTS | ||

| Product | Code | |

| 20207BO 300 | Red | |

| 20209BO 300 | Green | |

| 20208BO 300 | Mustard | |

| 20205BO 300 | Mid Grey | |

| 20212BO 300 | Dark Grey | |

| 20215BO 300 | Beige | |

| 20211BO 300 | Light Grey | |

| 47601 300 | Anthrasite grey | |