A special a.b.e.® Construction Chemicals waterproofing coating was selected for wide-spread sealing of surfaces at the new ultra-luxurious Royal Palace in Maseru.

Boksburg-based a.b.e.® is part of the CHRYSO Southern Africa Group.

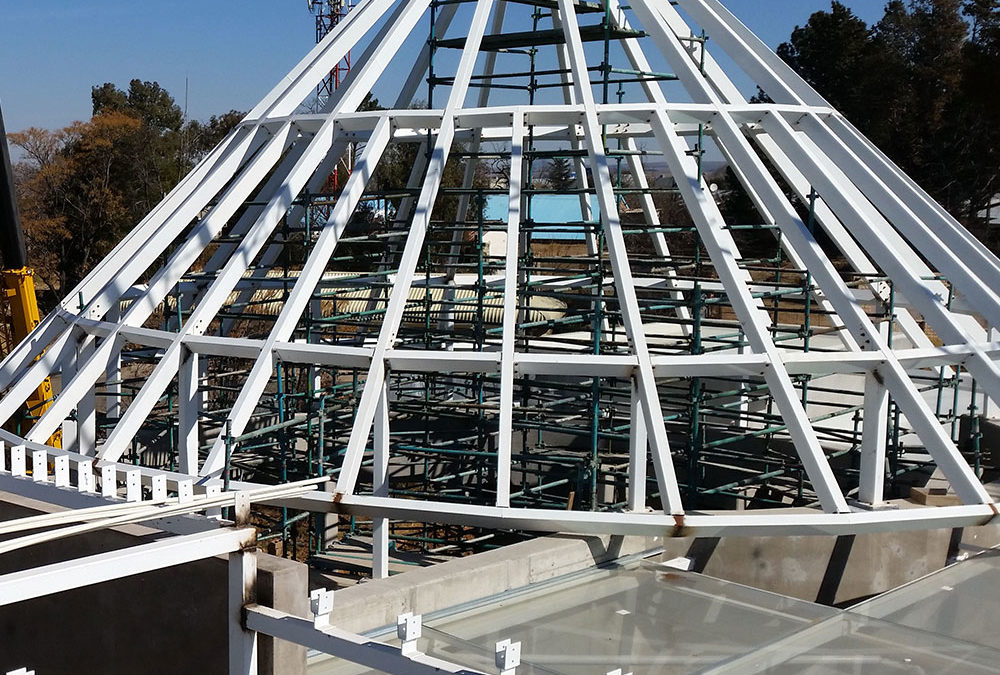

Noel Abendroth, a.b.e.® Polyurea Performance Coatings Manager, says VIP Polyurea Quick Spray Industrial pure polyurea coating has so far been applied to over 2 400 m² of diverse surfaces at the Royal Palace now being constructed by LSP Construction of Maseru. The VIP polyurea sealant was specified by LSP which is carrying out the large-scaled contract for the Government of Lesotho.

Among the many areas of the palace sealed with the pure polyurea coating were:

- Palace roofs;

- Roof gardens;

- Tanking for ground-level exotic gardens;

- Guest house roof; and

- Tennis Clubhouse roof.