General purpose white Portland cement (CEM II/B-L 42.5N)

abe® CEM-blanc is a general purpose white Portland cement, specially manufactured to provide superior early strength with the added advantage of providing a wide range of aesthetic and decorative opportunities due to its key features of whiteness, high strength and durability. In addition to affording great design and colour versatility abe® CEM-blanc complies fully with the requirements specified in SANS 50197-1 for type CEM II 42.5N cement.

Uses

A wide variety of white and light coloured finishes can be produced with selected white/light coloured aggregates or with pigments. abe® CEM-blanc white cement is ideally suited for the following applications:

- High early strength specialist products particularly where the added feature of whiteness and improved aesthetics is desirable

- Coloured mortars, plasters and screeds

- Architectural colour finishes in buildings, bridges,retaining walls

- Readymix and precast walls, columns and floors

- Decorative pavements, blocks and pavers

- Formulated, pre-bagged repairs, tile grouts, adhesives and screeds

- Swimming pool finishes and plaster

- Exposed aggregate finishes

Colour

White

Advantages

- By using the best available ‘technical grade’ limestone/clinker, abe® CEM-blanc is milled to a carefully controlled fineness to ensure high early and late age strength gain.

- Concrete and cement bound products made withabe® CEM-blanc is very easy to colour using normal pigments resulting in a wide colour spectrum with superior colour consistency.

- abe® CEM-blanc’s whiteness, consistent quality, versatility and strength make it the preferred choice for both readymix and precast producers.

- abe® CEM-blanc as a CEM II 42.5N product can be further blended with fly ash, condensed silica fume, ground granulated blast furnace slag (GGBS) and limestone. Blending with other extender types/supplementary cementitious materials can slow early strength development and may influence whiteness.

- High performance ensures that the product’s cost-in-use or cost efficiency is far superior. This higher performance often leads to lower cement contents or higher replacement levels of less expensive input materials when using be® CEM-blanc. This results in improved cost versus performance against other less expensive/lower performance white cements.

- Contant quality control and monitoring guarantees high performance in the 42.5N strength class.

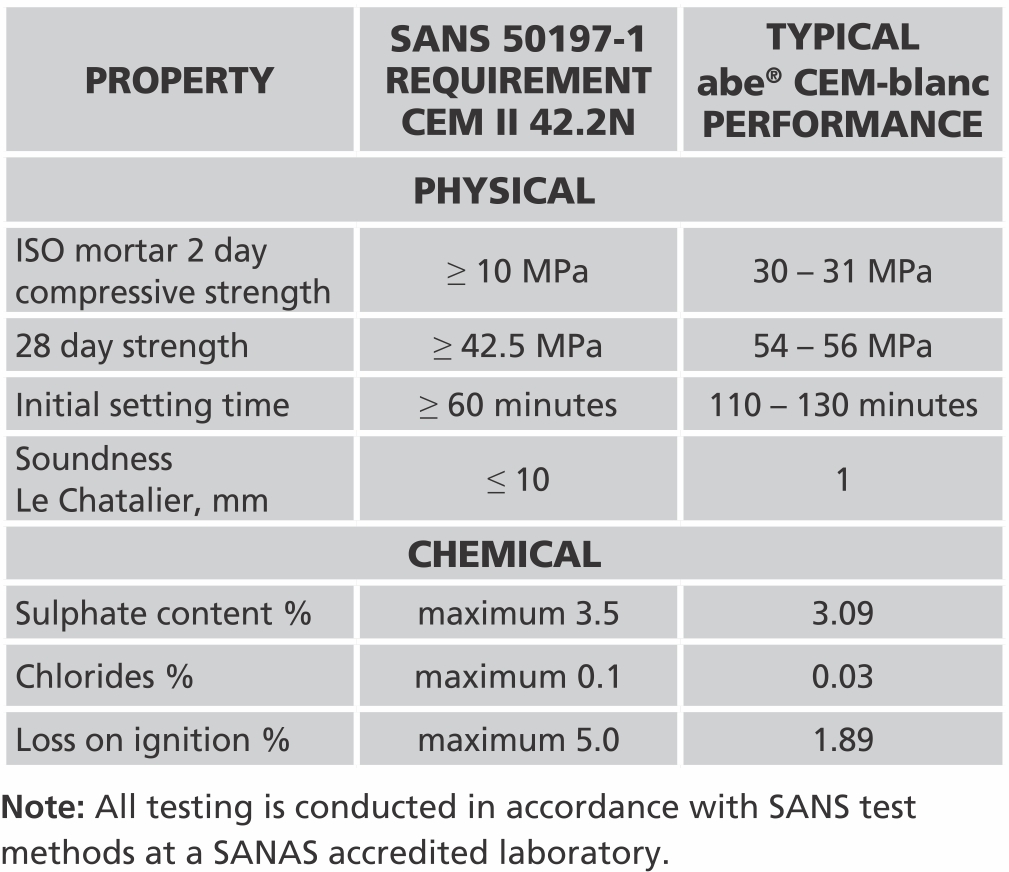

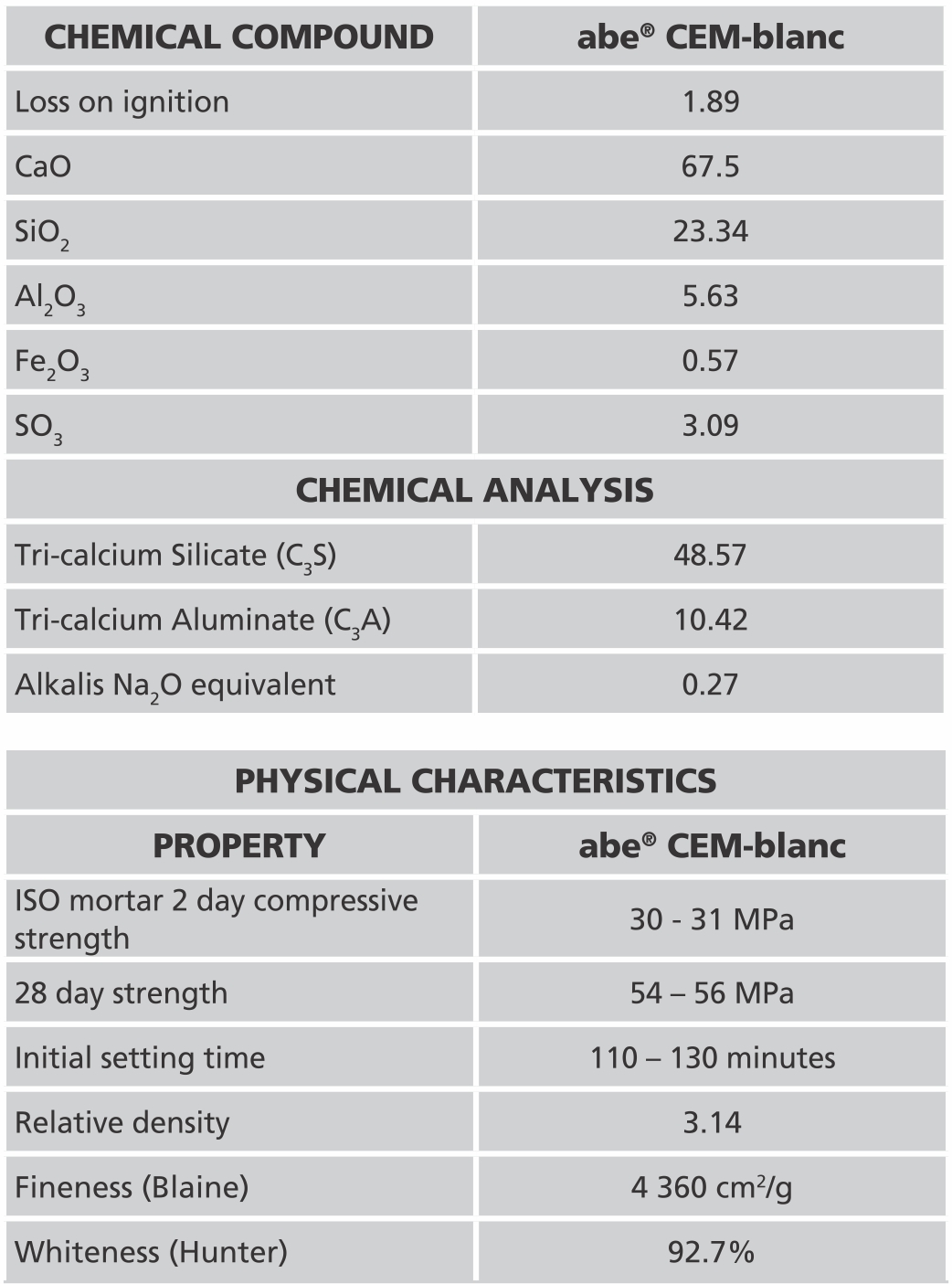

Typical performance in relation to SANS 50197-1 requirements with indicative values achieved by abe®CEM-blanc

Mix design and formulation optimisation

The proportioning of constituent materials in a concrete mix (or cement bound formulations) is a complex matter which can be influenced by a number of factors. We recommend that laboratory and field trails be conducted (as appropriate) with available materials to ascertain optimum cement contents for specific classes of concrete and product formulations.

abe® CEM-blanc is compatible with a wide range of admixtures that comply with the requirements of South African National Standard (SANS) 50934: Chemical admixtures for Concrete. These include (but are not restricted to) many different admixture types namely plasticisers, superplasticisers, air entrainers, thickening agents and accelerators. Admixtures in concrete should always be used in strict accordance with the manufacturers’ specifications and recommendations and it is advisable that trials are conducted to ensure that the admixture does not adversely affect the product colour.

Curing methods and best practice

The term curing refers to methods to prevent moisture loss from exposed surfaces of concrete in the first 7 days after casting. It is extremely important that an effective curing regime is followed to ensure that no cracking occurs and that the full strength potential of concrete products is realised. This can be achieved in a number of ways, some of the most common methods include:

- Ponding with clean water

- Covering with impermeable sheeting ensuring that edges are held down and secure

- Spraying with a propriety curing compound/membrane preferably pigmented to ensure full and adequate coverage

Handling and Storage

The shelf life of white Portland cement products is totally dependent on the storage conditions:

- Store in a dry enclosed area

- Store off the floor preferably on wooden pallets, with plastic sheeting

- If the cement is stored in jumbo bags, ensure that bags/inner liners are sealed during storage

It is suggested that cement products which have been stored in excess of six (6) months be re-tested prior to use.

Health & Safety

Portland cement products are highly alkaline materials and are directly affected by exposure to water. Suitable Personal Protective Equipment (PPE) and safety attire should be worn to prevent dust inhalation and direct skin contact. Full health, safety, storage and disposal information is available on the abe® CEM-blanc material safety data sheet (MSDS), a copy of which is available on request.

Important Notice

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or continuous control over where and how a.b.e.® products are applied.

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total

requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction

technology.