Concrete Sealer for Cementitious Screeds

abeseal finisol is a water-based concrete sealer that is moisture insensitive (tolerant) and dries clear.

abeseal finisol has a tracing effect that helps to see the treated areas and to optimise the application rate. The white aspect totally disappears when dry.

abeseal finisol improves surface toughness, abrasion and wear resistance (ISO 11-998 and ASTM D24-56).

abeseal finisol does not modify the aspect and the colour of the substrate on which it is applied. It is non-yellowing over time (Accelerated ageing test – NF EN ISO 11-507).

Uses

Sealer:

- A seal coat for cementitious screeds, abescreed duraTop and abescreed SLCP

- abeseal finisol is designed to protect aesthetic concrete, especially on concrete at early ages (12 to 24 hours after concrete casting). This product is particularly adapted to protect exposed aggregate concrete, on which it can be applied immediately after the wash out of the surface retarder

- Decorative concrete, pavers, slabs and street furniture

- Precast concrete elements

- Pigmented screed sealing and colour enhancing

- Can be overcoated with water based systems for demarcation lines

Advantages

- Protects the exposed aggregate surfaces

- Non-yellowing

- Solvent-free system; low odour

- Film-forming sealer that reduces stains

- Oleophobic and hydrophobic functions, offers protection against oils, water and dust

- Increases durability of the surface

- Reduces the appearance of efflorescence

- Economical sealer

- Film forming dries to a clear film

- Seals moisture, allows vapour transmission

- Water-based makes it safe for users.

- Easy to appl

- Easy to clean equipment while still wet

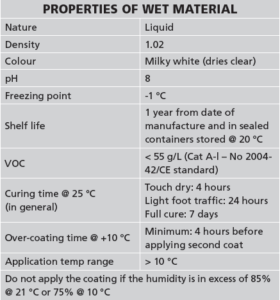

Properties of Wet Material

Surface Preparation

Surfaces must be clean, mechanically sound, free of laitance, nibs, dust, curing membrane, grease, oil and any excess water.

Precautions:

Protect the surface from frost

Application

abeseal finisol is ready-to-use and can be applied by brush, roller or spray for both interior and exterior applications.

Sealing

The application rate depends on the porosity of the surface to be treated. The average coverage for is 5 m2/L/coat. A minimum of 2 two coats are required, by the addition of any further coats the surface will tend toward a gloss finish.

abeseal finisol may be applied to a damp substrate that is free of excess water or puddles.

Apply the product in a uniform manner without any rundowns or puddles.

Wait 4 hours before applying a second coat, provided that ambient temperatures are not below 10 °C.

In case of vertical application, the product can be applied on porous and non-greasy substrates. Spraying will be done using airless process (pressure 5 – 6 bar).

In case of over-application, droplets can appear, but after drying, abeseal finisol is perfectly smooth.

Precautions:

- In windy conditions the surface needs to be protected against dirt and dust contamination while it is still wet.

- Excess water needs to be brushed away to obtain a damp surface.

- Do not apply when it is wet or when temperatures are below 10 °C. This should also be respected when drying.

- Should the product freeze, it will recover its properties. After thawing, efficient agitation is necessary until product is entirely homogeneous again.

Coverage

Sealing

4 to 6 m2/L/coat, subject to the surface profile and porosity of the surface, a minimum of 2 coats are required.

Cleaning

While the product is still wet wash the tools with clean water.

Packaging

abeseal finisol is supplied in 20 L and 5 L plastic containers.

5ℓ (code: 67105005)

20ℓ (code: 67105020)

Handling & Storage

abeseal finisol has a shelf life of 1 year if kept in a dry, cool store in the original, unopened packs.

Health & Safety

Product safety information required for safe use is not included. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. The safety data sheet is available from your local a.b.e.® sales representative.

Important Note

This data sheet is issued as a guide to the use of the product(s) concerned. Whilst a.b.e.® endeavours to ensure that any advice, recommendation,

specification or information is accurate and correct, the company cannot accept any liability for application – because a.b.e.® has no direct or

continuous control over where and how a.b.e.® products are applied.

Further Information

Where other products are to be used in conjunction with this material, the relevant technical data sheets should be consulted to determine total

requirements.

a.b.e.® has a wealth of technical and practical experience built up over the years in the company’s pursuit of excellence in building and construction

technology.