Uses

As a grouting medium, either as supplied or converted into a mortar, for fixing dowel bars, bolts or other steel overhead or horizontally into concrete or rock. As a fast-setting non-flow adhesive. Grouting vertically downwards use epidermix® 395.

Advantages

- Will not drain from hole, including overhead.

- Stronger than surrounding concrete and steel.

- Maximum service temperature: 70 ºC.

- Compressive strength @ 25 ºC: 90 MPa at 7 days.

- Solvent resistance: aliphatic solvents, vegetable and mineral oils and greases, petroleum fuels.

- Excellent water resistance.

- Tensile strength: 21 MPa at 7 days.

- Overlap shear strength after: 1 day = 12.5 MPa, 7 days = 13.8 MPa, 14 days = 14.1 MPa.

Surface preparation

All surfaces must be clean, sound and dry.

Cast concrete must be free of all laitance, dust and foreign matter. Drilled concrete must be free of dust and debris and if wet-drilled must be dry and free of all traces of slurry. Any glaze caused by core drilling must be removed by mechanical roughening to ensure good bonding between the adhesive and the concrete rock surface. Close fitting burrs attached to a long shaft mounted in a power drill will aid in this respect. Smooth steel should be abrasive blast cleaned and must be free of scale, rust and oily material. Deformed and threaded bars should be oil and grease free and preferably free of rust and scale.

Bonding/priming

Self-priming.

Mixing

Mix both containers individually and ideally use a can opener to remove the lip of the containers. Transfer complete contents of both containers to a large clean board or plate, setting up the components side by side and not one on top of the other. Do not combine the components until other aspects of the job are ready. When ready to mix, combine the ingredients together and blend, using at least two trowels or spatula, until the compound is completely mixed. If a mortar is required, add an equivalent volume of silica grit and continue mixing until a homogeneous material is obtained.

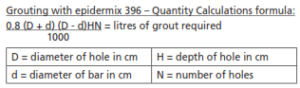

Coverage

These figures makes no allowance for site wastage of material.

Provided deformed or threaded steel, either mild or high tensile, is embedded at least 15 diameters it can be expected that any failure of the assembly will be due to tensile rupture of the steel. Thus epidermix® grouting allows the steel to develop its full design strength. Regarding the ratio of hole to rod diameter it has been shown that the ultimate coverage bond stress is at its highest at a ratio of 1.3. This reduces as the ratio increased to 1.67 thereafter remaining constant. By increasing the ratio from 1.3 to 1.5 the ultimate average bond stress is decreased some 15%. At a ratio of 1.67 the ultimate average bond stress has decreased some 20%.

Application

If grouting horizontally or overhead, a mastic gun is required with a length of plastic tubing of sufficient diameter to fit tightly over the gun’s nozzle.

The tube must be long enough to reach the back of the hole. Fill the gun with the mixed epoxy compound or mortar and pump material into the back of the hole, slowly withdrawing the tube until sufficient material has been deposited to fill the hole once the bar has been introduced.

The bar should be introduced with a rotary motion to ensure wetting of both bar and concrete, if it is important that the bar is truly horizontal a jig or template must be used until the compound has set.

Do not grout unfilled epidermix® 396 into a hole larger than 1.5 times bar diameter.

Cleaning

Tools, brushes and mixing equipment should be cleaned immediately after use and before material has set with abe® super brush cleaner followed by washing with soap and water.

Protection/maintenance on completion

Protect against traffic and spillage until material has cured..

Packaging

500 ml, metal container

Handling & storage

Shelf life of 24 months, but shorter if in extreme conditions. Keep tightly sealed in a dry cool place in the original packaging.

Caution

Temperature of metal to be grouted should not exceed 25 °C at time of grouting.

Health & safety

Product safety information required for safe use is not included. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. The safety data sheet is available from your local a.b.e.® Construction Chemicals branch.