Uses

As a grouting medium, either as supplied or converted into a mortar, for fixing starter bars, bolts and other similar items, vertically down into concrete or rock. As a flowable grout or bedding for areas of awkward access. As a fast-setting crack repairing compound.

Advantages

- Stronger than surrounding concrete and steel.

- Easy pouring for upstanding bolts and concrete road/ slab cracks.

- Easy access to narrow gap horizontal areas.

- Maximum service temperature: 70 ºC.

- Excellent water resistance.

- Compressive strength @ 25 ºC unfilled: 34 MPa at 7 days.

- Solvent resistance to: aliphatic solvents, vegetable and mineral oils and greases, petroleum fuels.

- Overlap shear strength after 1 day: 17.3 MPa, 7 days: 17 MPa, 14 days: 19.8 MPa.

Design Criteria

Given adequate concrete strength and provided that a bar of deformed or threaded steel, either mild or high tensile, is embedded to a depth of at least 15 diameters, it can be expected that any failure of the assembly will be due to tensile rupture of the steel. Thus epidermix® 395 grouting allows the steel and the concrete to operate at full design strength.

Regarding the diameter ratio of hole to rod, it has been shown that the ultimate average bond strength is at its maximum at a ratio of 1.3:1. Ultimate average bond stress reduces as the whole rod ratio increases to a value of 1.67:1. Thereafter it remains constant. An increase of diameter ratio from 1.3 to 1.67 will reduce the ultimate average bond strength by some 20%.

Surface Preparation

All surfaces must be clean, sound and dry. Cast concrete must be free of all laitance, dust and foreign matter. Drilled concrete and rock must be free of dust and debris and if wet-drilled must be dry and free of all traces of slurry. Any glaze caused by core drilling must be removed by mechanical roughening to ensure good bonding between the adhesive and the concrete/rock surface. Close-fitting burrs attached to a long shaft mounted in a power drill will aid in this respect. Pockets must be both free of standing water and surface-dry. Smooth steel should be abrasive blast cleaned, and must be free of scale, rust and oily material. Deformed and threaded bars should be oil and grease free and must be free of rust and scale.

Bonding / Priming

Self-priming.

Mixing

Stir both containers individually and ideally use a can opener to remove the lip of the containers. Add the entire contents of the activator tin to the base and stir with a flat paddle until an even streak-free mixture results. This takes at least five minutes. If a mortar is required, premix the base and activator and then add silica grit aggregate. Up to two volumes may be used and the whole mixture must be stirred until the aggregate is evenly wetted.

Application

For best results mixed material should be poured into the hole to such a level that when the bar is inserted, material displaced just reaches the top of the hole. Bar should be inserted into the compound with a rotary motion to ensure full wetting of both bar and concrete faces. Do NOT merely drop the bar in as this can result in air entrapment.

If the bar is already positioned, pour compound slowly into the annulus, punning with a piece of suitable wire to help release air bubbles. If it is important that the bar must remain vertical, a jig or template must be used until the compound has set.

Where epidermix® 395 mortar is being used to bed an object (i.e. fill a gap between horizontal surfaces) pouring must be done from one point only, to prevent air entrapment. Provision must be made for any entrapped air to escape by venting, if necessary. If shuttering has to be provided to retain the grout whilst setting, shutters must be treated with a release agent or faced with plastic sheeting. It will be necessary to provide an inlet point into the shuttering so that a head of compound can be built up to promote flow. Again venting must be provided.

Cleaning

Tools, brushes and mixing equipment should be cleaned immediately after use and before material has set with abe® super brush cleaner followed by washing with soap and water.

Protection/maintenance on completion

Protect against traffic and spillage until material has cured.

Packaging

500 ml, 1 L, 2 L

Handling & storage

Shelf life of 24 months, but shorter if in extreme conditions. Keep tightly sealed in a dry cool place in the original packaging.

Caution

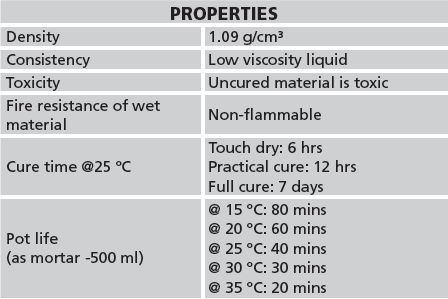

Temperature of metal to be grouted should not exceed 25 ºC at time of grouting. If application temperatures are above 30 ºC consult a.b.e.®’s Technical Department for special precautions.

Health & safety

Product safety information required for safe use is not included. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. The safety data sheet is available from your local a.b.e.® Construction Chemicals branch.